Page 191 - Chemical and process design handbook

P. 191

Speight_Part II_C 11/7/01 3:08 PM Page 2.132

2.132 MANUFACTURE OF CHEMICALS

limestone limestone

1

CO

2

coke coke

2

3

air air

CaO

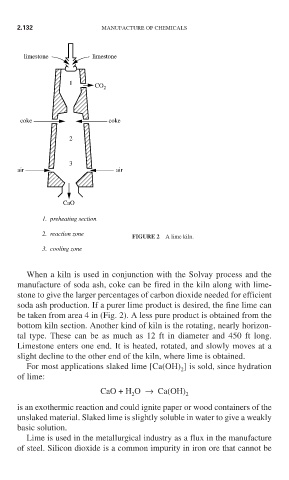

1. preheating section

2. reaction zone

FIGURE 2 A lime kiln.

3. cooling zone

When a kiln is used in conjunction with the Solvay process and the

manufacture of soda ash, coke can be fired in the kiln along with lime-

stone to give the larger percentages of carbon dioxide needed for efficient

soda ash production. If a purer lime product is desired, the fine lime can

be taken from area 4 in (Fig. 2). A less pure product is obtained from the

bottom kiln section. Another kind of kiln is the rotating, nearly horizon-

tal type. These can be as much as 12 ft in diameter and 450 ft long.

Limestone enters one end. It is heated, rotated, and slowly moves at a

slight decline to the other end of the kiln, where lime is obtained.

For most applications slaked lime [Ca(OH) ] is sold, since hydration

2

of lime:

CaO + H O → Ca(OH)

2 2

is an exothermic reaction and could ignite paper or wood containers of the

unslaked material. Slaked lime is slightly soluble in water to give a weakly

basic solution.

Lime is used in the metallurgical industry as a flux in the manufacture

of steel. Silicon dioxide is a common impurity in iron ore that cannot be