Page 123 - Chemical engineering design

P. 123

103

FUNDAMENTALS OF ENERGY BALANCES

Waste-heat boilers are often used to recover heat from furnace flue gases and the process

gas streams from high-temperature reactors. The pressure, and superheat temperature, of

the stream generated will depend on the temperature of the hot stream and the approach

temperature permissible at the boiler exit (see Chapter 12). As with any heat-transfer

equipment, the area required will increase as the mean temperature driving force (log

mean T) is reduced. The permissible exit temperature may also be limited by process

considerations. If the gas stream contains water vapour and soluble corrosive gases, such

as HCl or SO 2 , the exit gases temperature must be kept above the dew point.

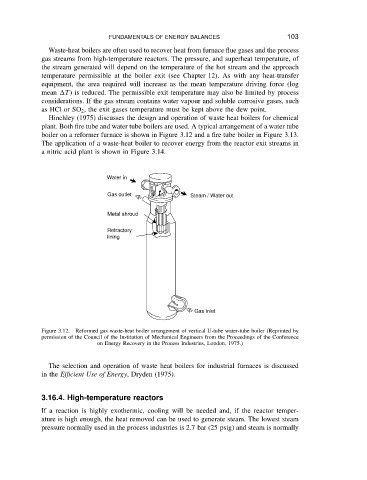

Hinchley (1975) discusses the design and operation of waste heat boilers for chemical

plant. Both fire tube and water tube boilers are used. A typical arrangement of a water tube

boiler on a reformer furnace is shown in Figure 3.12 and a fire tube boiler in Figure 3.13.

The application of a waste-heat boiler to recover energy from the reactor exit streams in

a nitric acid plant is shown in Figure 3.14.

Water in

Gas outlet Steam / Water out

Metal shroud

Refractory

lining

Gas inlet

Figure 3.12. Reformed gas waste-heat boiler arrangement of vertical U-tube water-tube boiler (Reprinted by

permission of the Council of the Institution of Mechanical Engineers from the Proceedings of the Conference

on Energy Recovery in the Process Industries, London, 1975.)

The selection and operation of waste heat boilers for industrial furnaces is discussed

in the Efficient Use of Energy, Dryden (1975).

3.16.4. High-temperature reactors

If a reaction is highly exothermic, cooling will be needed and, if the reactor temper-

ature is high enough, the heat removed can be used to generate steam. The lowest steam

pressure normally used in the process industries is 2.7 bar (25 psig) and steam is normally