Page 124 - Chemical engineering design

P. 124

104

CHEMICAL ENGINEERING

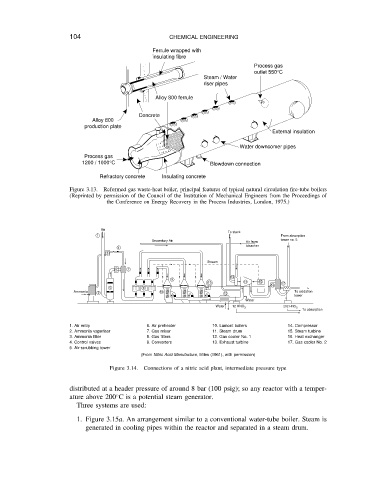

Ferrule wrapped with

insulating fibre

Process gas

outlet 550°C

Steam / Water

riser pipes

Alloy 800 ferrule

Concrete

Alloy 800

production plate

External insulation

Water downcomer pipes

Process gas

1200 / 1000°C Blowdown connection

Refractory concrete Insulating concrete

Figure 3.13. Reformed gas waste-heat boiler, principal features of typical natural circulation fire-tube boilers

(Reprinted by permission of the Council of the Institution of Mechanical Engineers from the Proceedings of

the Conference on Energy Recovery in the Process Industries, London, 1975.)

Air

To stack

1 From absorption

Secondary Air Air from tower no. 5

bleacher

4

3

Stream

6 7 13

5 .... 8 .... 9 11 14 15 16 17

....

....

Ammonia 2 10 12 To oxidation

tower

12 HNO 3 202 HNO 3 To absorption

Water Water

1. Air entry 6. Air preheater 10. Lamont boilers 14. Compressor

2. Ammonia vaporiser 7. Gas mixer 11. Steam drum 15. Steam turbine

3. Ammonia filter 8. Gas filters 12. Gas cooler No. 1 16. Heat exchanger

4. Control valves 9. Converters 13. Exhaust turbine 17. Gas cooler No. 2

5. Air-scrubbing tower

(From Nitric Acid Manufacture, Miles (1961), with permission)

Figure 3.14. Connections of a nitric acid plant, intermediate pressure type

distributed at a header pressure of around 8 bar (100 psig); so any reactor with a temper-

Ž

ature above 200 C is a potential steam generator.

Threesystems areused:

1. Figure 3.15a. An arrangement similar to a conventional water-tube boiler. Steam is

generated in cooling pipes within the reactor and separated in a steam drum.