Page 174 - Chemical engineering design

P. 174

FLOW-SHEETING

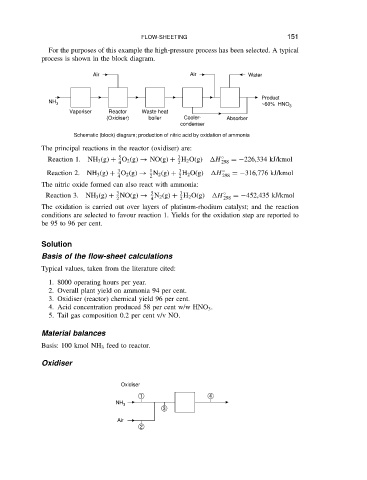

For the purposes of this example the high-pressure process has been selected. A typical

process is shown in the block diagram. 151

Air Air Water

Product

NH 3

~60% HNO 3

Vaporiser Reactor Waste heat

(Oxidiser) boiler Cooler- Absorber

condenser

Schematic (block) diagram; production of nitric acid by oxidation of ammonia

The principal reactions in the reactor (oxidiser) are:

3

5

Reaction 1. NH 3 (g) C O 2 (g) ! NO(g) C H 2 O(g) H Ž D 226,334 kJ/kmol

4 2 298

1

3

3

Reaction 2. NH 3 (g) C O 2 (g) ! N 2 (g) C H 2 O(g) H Ž D 316,776 kJ/kmol

4 2 2 298

The nitric oxide formed can also react with ammonia:

3

5

3

Reaction 3. NH 3 (g) C NO(g) ! N 2 (g) C H 2 O(g) H Ž D 452,435 kJ/kmol

2 4 2 298

The oxidation is carried out over layers of platinum-rhodium catalyst; and the reaction

conditions are selected to favour reaction 1. Yields for the oxidation step are reported to

be 95 to 96 per cent.

Solution

Basis of the flow-sheet calculations

Typical values, taken from the literature cited:

1. 8000 operating hours per year.

2. Overall plant yield on ammonia 94 per cent.

3. Oxidiser (reactor) chemical yield 96 per cent.

4. Acid concentration produced 58 per cent w/w HNO 3 .

5. Tail gas composition 0.2 per cent v/v NO.

Material balances

Basis: 100 kmol NH 3 feed to reactor.

Oxidiser

Oxidiser

1 4

NH 3

3

Air

2