Page 211 - Chemical engineering design

P. 211

188

CHEMICAL ENGINEERING

LEESLEY, M. E. (ed.) (1982) Computer Aided Process Plant Design (Gulf).

MAH,S. H. and SEIDER, W. D. (eds) (1980) Foundations of Computer-aided Process Design (2 vols.)

(Engineering Foundation/AIChemE).

MASON, J. C. (1984) BASIC Matrix Methods (Butterworths).

NAGIEV, M. F. (1964) The Theory of Recycle Processes in Chemical Engineering (Pergamon).

PANTELIDES, C. C. (1988) Comp. and Chem. Eng., 12, 745. SpeedUp recent advances in process engineering.

PREECE, P. E. (1986) Chem. Eng., London. No. 426, 87. The making of PFG and PIG.

PREECE,P. E. and STEPHENS, M. B. (1989) IChemE Symposium Series No. 114, 89, PROCEDE opening

windows on the design process.

PREECE,P. E., KIFT,M. H. and GRILLS, D. M. (1991) Computer-Orientated Process Design, Proceedings of

COPE, Barcelona, Spain, Oct. 14 16, 209, A graphical user interface for computer aided process design.

ROSEN, E. M. (1962) Chem. Eng. Prog. 58 (Oct.) 69. A machine computation method for performing material

balances.

VELA, M. A. (1961) Pet. Ref. 40 (May) 247, (June) 189 (in two parts). Use of fractions for recycle balances.

WELLS,G. L. and ROSE, L. M. (1986) The Art of Chemical Process Design (Elsevier).

WESTERBERG,A. W., HUTCHINSON,H. P., MOTARD,R. L. and WINTER, P. (1979) Process Flow-sheeting

(Cambridge U.P.).

WESTLAKE, J. R. (1968) A handbook of numerical matrix inversion and solution of linear equations (Wiley).

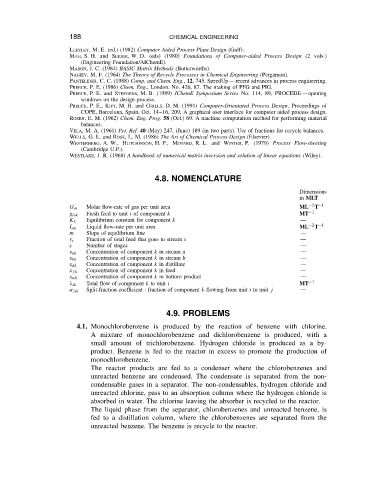

4.8. NOMENCLATURE

Dimensions

in MLT

T

G m Molar flow-rate of gas per unit area ML 2 1

g iok Fresh feed to unit i of component k MT 1

K k Equilibrium constant for component k

T

L m Liquid flow-rate per unit area ML 2 1

m Slope of equilibrium line

r s Fraction of total feed that goes to stream s

s Number of stages

x ak Concentration of component k in stream a

x bk Concentration of component k in stream b

x dk Concentration of component k in distillate

x fk Concentration of component k in feed

x wk Concentration of component k in bottom product

ik Total flow of component k to unit i MT 1

˛ jik Split-fraction coefficient : fraction of component k flowing from unit i to unit j

4.9. PROBLEMS

4.1. Monochlorobenzene is produced by the reaction of benzene with chlorine.

A mixture of monochlorobenzene and dichlorobenzene is produced, with a

small amount of trichlorobenzene. Hydrogen chloride is produced as a by-

product. Benzene is fed to the reactor in excess to promote the production of

monochlorobenzene.

The reactor products are fed to a condenser where the chlorobenzenes and

unreacted benzene are condensed. The condensate is separated from the non-

condensable gases in a separator. The non-condensables, hydrogen chloride and

unreacted chlorine, pass to an absorption column where the hydrogen chloride is

absorbed in water. The chlorine leaving the absorber is recycled to the reactor.

The liquid phase from the separator, chlorobenzenes and unreacted benzene, is

fed to a distillation column, where the chlorobenzenes are separated from the

unreacted benzene. The benzene is recycle to the reactor.