Page 206 - Chemical engineering design

P. 206

A] ... .. .. .A/... .. .. .B/... .. .. .C/.. .. ... .D/. .. ... ..E/... ... ..F/.. .. ... .G/.. .. .. ..H

98 FLOW-SHEETING 183

99

100

101 Recycle flow composition

102

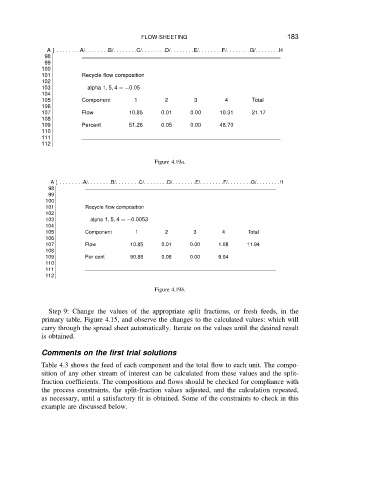

103 alpha 1, 5, 4 D 0.05

104

105 Component 1 2 3 4 Total

106

107 Flow 10.85 0.01 0.00 10.31 21.17

108

109 Percent 51.26 0.05 0.00 48.70

110

111

112

Figure 4.19a.

A] .. .. .. . .A/... .. .. .B/.. ... .. .C/.. ... .. .D/.. .. ... .E/.. .. .. ..F/. ... .. ..G/.... .. ..H

98

99

100

101 Recycle flow composition

102

103 alpha 1, 5, 4 D 0.0053

104

105 Component 1 2 3 4 Total

106

107 Flow 10.85 0.01 0.00 1.08 11.94

108

109 Per cent 90.88 0.08 0.00 9.04

110

111

112

Figure 4.19b.

Step 9: Change the values of the appropriate split fractions, or fresh feeds, in the

primary table, Figure 4.15, and observe the changes to the calculated values: which will

carry through the spread sheet automatically. Iterate on the values until the desired result

is obtained.

Comments on the first trial solutions

Table 4.3 shows the feed of each component and the total flow to each unit. The compo-

sition of any other stream of interest can be calculated from these values and the split-

fraction coefficients. The compositions and flows should be checked for compliance with

the process constraints, the split-fraction values adjusted, and the calculation repeated,

as necessary, until a satisfactory fit is obtained. Some of the constraints to check in this

example are discussed below.