Page 250 - Chemical engineering design

P. 250

226

CHEMICAL ENGINEERING

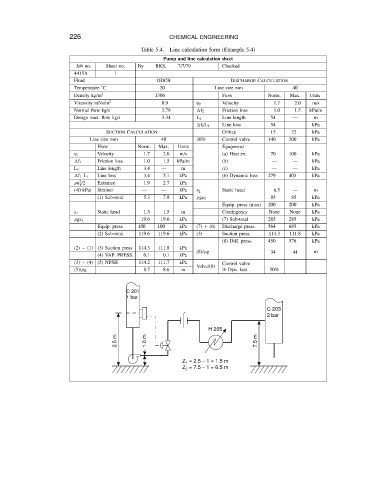

Table 5.4.

Line calculation form (Example 5.4)

Pump and line calculation sheet

Job no. Sheet no. By RKS, 7/7/79 Checked

4415A 1

Fluid ODCB DISCHARGE CALCULATION

Temperature °C 20 Line size mm 40

Density kg/m 3 1306 Flow Norm. Max. Units

Viscosity mNs/m 2 0.9 u 2 Velocity 1.7 2.0 m/s

Normal flow kg/s 2.78 f 2 Friction loss 1.0 1.5 kPa/m

Design max. flow kg/s 3.34 L 2 Line length 54 m

Line loss 54 kPa

f 2 L 2

SUCTION CALCULATION Orifice 15 22 kPa

Line size mm 40 30% Control valve 140 200 kPa

Flow Norm. Max. Units Equipment

u 1 Velocity 1.7 2.0 m/s (a) Heat ex. 70 100 kPa

Friction loss 1.0 1.5 kPa/m (b) kPa

f 1

L 1 Line length 3.4 m (c) kPa

Line loss 3.4 5.1 kPa (6) Dynamic loss 279 403 kPa

f 1 L 1

2

u /2 Entrance 1.9 2.7 kPa

1

(40 kPa) Strainer kPa z 2 Static head 6.5 m

(1) Sub-total 5.3 7.8 kPa gz 2 85 85 kPa

Equip. press (max) 200 200 kPa

z 1 Static head 1.5 1.5 m Contingency None None kPa

gz 1 19.6 19.6 kPa (7) Sub-total 285 285 kPa

Equip. press 100 100 kPa (7) C (6) Discharge press. 564 685 kPa

(2) Sub-total 119.6 119.6 kPa (3) Suction press. 114.3 111.8 kPa

(8) Diff. press. 450 576 kPa

(2) (1) (3) Suction press 114.3 111.8 kPa

(8)/ g 34 44 m

(4) VAP. PRESS. 0.1 0.1 kPa

(3) (4) (5) NPSH 114.2 111.7 kPa Control valve

Valve/(6)

(5)/ g 8.7 8.6 m % Dyn. loss 50%

C 201

1 bar

C 203

2 bar

H 205

2.5 m 1.0 m 7.5 m

Z = 2.5 − 1 = 1.5 m

1

Z = 7.5 − 1 = 6.5 m

2