Page 254 - Chemical engineering design

P. 254

230

(a) CHEMICAL ENGINEERING

(b)

(c) (d)

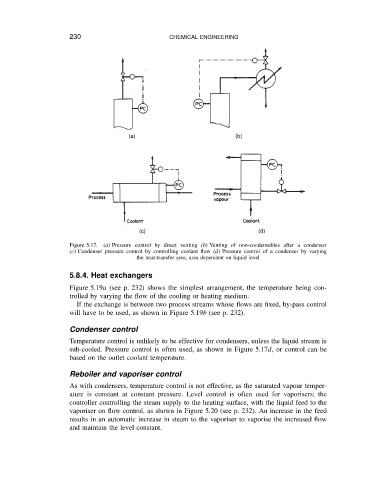

Figure 5.17. (a) Pressure control by direct venting (b) Venting of non-condensables after a condenser

(c) Condenser pressure control by controlling coolant flow (d) Pressure control of a condenser by varying

the heat-transfer area, area dependent on liquid level

5.8.4. Heat exchangers

Figure 5.19a (see p. 232) shows the simplest arrangement, the temperature being con-

trolled by varying the flow of the cooling or heating medium.

If the exchange is between two process streams whose flows are fixed, by-pass control

will have to be used, as shown in Figure 5.19b (see p. 232).

Condenser control

Temperature control is unlikely to be effective for condensers, unless the liquid stream is

sub-cooled. Pressure control is often used, as shown in Figure 5.17d, or control can be

based on the outlet coolant temperature.

Reboiler and vaporiser control

As with condensers, temperature control is not effective, as the saturated vapour temper-

ature is constant at constant pressure. Level control is often used for vaporisers; the

controller controlling the steam supply to the heating surface, with the liquid feed to the

vaporiser on flow control, as shown in Figure 5.20 (see p. 232). An increase in the feed

results in an automatic increase in steam to the vaporiser to vaporise the increased flow

and maintain the level constant.