Page 8 - Chemical engineering design

P. 8

vii

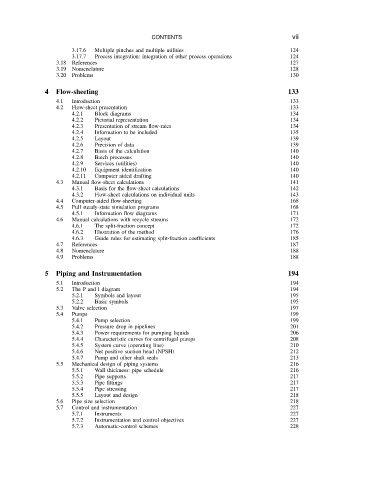

CONTENTS

3.17.6

124

3.17.7 Multiple pinches and multiple utilities 124

Process integration: integration of other process operations

3.18 References 127

3.19 Nomenclature 128

3.20 Problems 130

4 Flow-sheeting 133

4.1 Introduction 133

4.2 Flow-sheet presentation 133

4.2.1 Block diagrams 134

4.2.2 Pictorial representation 134

4.2.3 Presentation of stream flow-rates 134

4.2.4 Information to be included 135

4.2.5 Layout 139

4.2.6 Precision of data 139

4.2.7 Basis of the calculation 140

4.2.8 Batch processes 140

4.2.9 Services (utilities) 140

4.2.10 Equipment identification 140

4.2.11 Computer aided drafting 140

4.3 Manual flow-sheet calculations 141

4.3.1 Basis for the flow-sheet calculations 142

4.3.2 Flow-sheet calculations on individual units 143

4.4 Computer-aided flow-sheeting 168

4.5 Full steady-state simulation programs 168

4.5.1 Information flow diagrams 171

4.6 Manual calculations with recycle streams 172

4.6.1 The split-fraction concept 172

4.6.2 Illustration of the method 176

4.6.3 Guide rules for estimating split-fraction coefficients 185

4.7 References 187

4.8 Nomenclature 188

4.9 Problems 188

5 Piping and Instrumentation 194

5.1 Introduction 194

5.2 The P and I diagram 194

5.2.1 Symbols and layout 195

5.2.2 Basic symbols 195

5.3 Valve selection 197

5.4 Pumps 199

5.4.1 Pump selection 199

5.4.2 Pressure drop in pipelines 201

5.4.3 Power requirements for pumping liquids 206

5.4.4 Characteristic curves for centrifugal pumps 208

5.4.5 System curve (operating line) 210

5.4.6 Net positive suction head (NPSH) 212

5.4.7 Pump and other shaft seals 213

5.5 Mechanical design of piping systems 216

5.5.1 Wall thickness: pipe schedule 216

5.5.2 Pipe supports 217

5.5.3 Pipe fittings 217

5.5.4 Pipe stressing 217

5.5.5 Layout and design 218

5.6 Pipe size selection 218

5.7 Control and instrumentation 227

5.7.1 Instruments 227

5.7.2 Instrumentation and control objectives 227

5.7.3 Automatic-control schemes 228