Page 12 - Chemical engineering design

P. 12

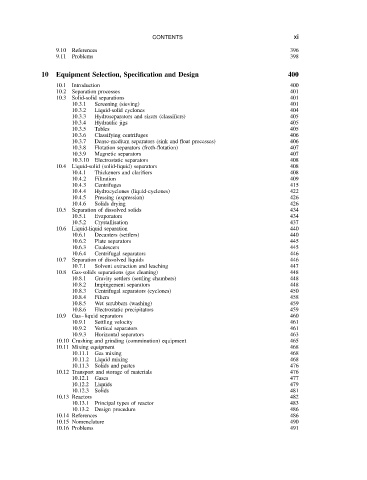

xi

9.10

Problems

398

9.11 References CONTENTS 396

10 Equipment Selection, Specification and Design 400

10.1 Introduction 400

10.2 Separation processes 401

10.3 Solid-solid separations 401

10.3.1 Screening (sieving) 401

10.3.2 Liquid-solid cyclones 404

10.3.3 Hydroseparators and sizers (classifiers) 405

10.3.4 Hydraulic jigs 405

10.3.5 Tables 405

10.3.6 Classifying centrifuges 406

10.3.7 Dense-medium separators (sink and float processes) 406

10.3.8 Flotation separators (froth-flotation) 407

10.3.9 Magnetic separators 407

10.3.10 Electrostatic separators 408

10.4 Liquid-solid (solid-liquid) separators 408

10.4.1 Thickeners and clarifiers 408

10.4.2 Filtration 409

10.4.3 Centrifuges 415

10.4.4 Hydrocyclones (liquid-cyclones) 422

10.4.5 Pressing (expression) 426

10.4.6 Solids drying 426

10.5 Separation of dissolved solids 434

10.5.1 Evaporators 434

10.5.2 Crystallisation 437

10.6 Liquid-liquid separation 440

10.6.1 Decanters (settlers) 440

10.6.2 Plate separators 445

10.6.3 Coalescers 445

10.6.4 Centrifugal separators 446

10.7 Separation of dissolved liquids 446

10.7.1 Solvent extraction and leaching 447

10.8 Gas-solids separations (gas cleaning) 448

10.8.1 Gravity settlers (settling chambers) 448

10.8.2 Impingement separators 448

10.8.3 Centrifugal separators (cyclones) 450

10.8.4 Filters 458

10.8.5 Wet scrubbers (washing) 459

10.8.6 Electrostatic precipitators 459

10.9 Gas liquid separators 460

10.9.1 Settling velocity 461

10.9.2 Vertical separators 461

10.9.3 Horizontal separators 463

10.10 Crushing and grinding (comminution) equipment 465

10.11 Mixing equipment 468

10.11.1 Gas mixing 468

10.11.2 Liquid mixing 468

10.11.3 Solids and pastes 476

10.12 Transport and storage of materials 476

10.12.1 Gases 477

10.12.2 Liquids 479

10.12.3 Solids 481

10.13 Reactors 482

10.13.1 Principal types of reactor 483

10.13.2 Design procedure 486

10.14 References 486

10.15 Nomenclature 490

10.16 Problems 491