Page 176 - Chemical process engineering design and economics

P. 176

158 Chapter 4

For the outside-packed lantern ring, the shell and tube-side fluids will not mix

within the shell. If the packing leaks, then the liquid will flow through the weep

holes in the lantern ring and drop to the floor. This design will not be satisfactory

for dangerous liquids unless a means for collecting the liquid safely is devised

This particular design is limited to 11.4 bar (11.3 arm) and 160°C (320 °F).

When higher shell-side temperatures and pressures than are attainable with a

packing-type seal are required, then the inside-split backing-ring design is used.

This design uses only gaskets as shown in Figure 4.1. To remove the tube bundle

for maintenance requires removing the front end, and the split ring, and the float-

ing-head cover at the back end. Because no seal can be guaranteed to be leak

proof, there is the possibility that shell-side and tube-side fluids could mix so that

this design is limited to fluids that can mix without creating a hazard.

The final heat-exchanger design considered is the kettle-type reboiler,

shown in Figure 4.1. The boiling fluid, which could be a refrigerant or other proc-

ess fluids, is placed on the shell side. In this design, the shell is enlarged to allow

some separation of entrained liquid droplets in the vapor. Also, the tube bundle

can be removed for maintenance. As was the case for the split-ring design, the

kettle reboiler should not be used if mixing of the shell-side and tube-side fluids

creates a hazard. The tubes in the kettle reboiler are free to expand in the shell.

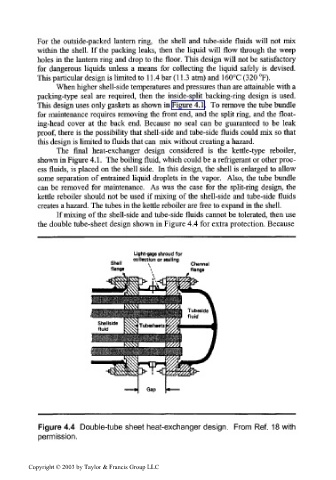

If mixing of the shell-side and tube-side fluids cannot be tolerated, then use

the double tube-sheet design shown in Figure 4.4 for extra protection. Because

Light-gage shroud for

collection or sealing

\ Channel

flange

Figure 4.4 Double-tube sheet heat-exchanger design. From Ref. 18 with

permission.

Copyright © 2003 by Taylor & Francis Group LLC