Page 221 - Chemical process engineering design and economics

P. 221

204 Chapter 5

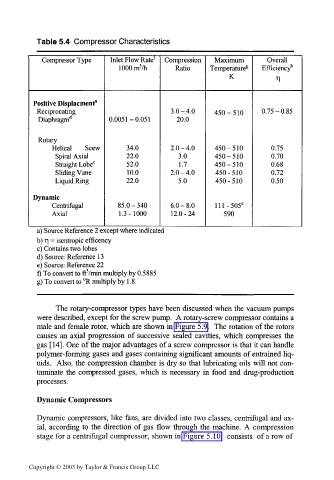

Table 5.4 Compressor Characteristics

Compressor Type Inlet Flow Rate' Compression Maximum Overall

lOOOrrrVh Ratio Temperature 8 Efficiency b

K Tl

Positive Displacment*

Reciprocating 3.0-4.0 450-510 0.75-0.85

Diaphragm d 0.0051-0.051 20.0

Rotary

Helical Scew 34.0 2.0-4.0 450-510 0.75

Spiral Axial 22.0 3.0 450-510 0.70

Straight Lobe c 52.0 1.7 450-510 0.68

Sliding Vane 10.0 2.0-4.0 450-510 0.72

Liquid Ring 22.0 5.0 450-510 0.50

Dynamic

Centrifugal 85.0 - 340 6.0-8.0 lll-505 e

Axial 1.3-1000 12.0-24 590

a) Source Reference 2 except where indicated

b) T] = isentropic efficency

c) Contains two lobes

d) Source: Reference 13

e) Source: Reference 22

f) To convert to ftVmin multiply by 0.5885

g) To convert to °R multiply by 1.8.

The rotary-compressor types have been discussed when the vacuum pumps

were described, except for the screw pump. A rotary-screw compressor contains a

male and female rotor, which are shown in Figure 5.9. The rotation of the rotors

causes an axial progression of successive sealed cavities, which compresses the

gas [14]. One of the major advantages of a screw compressor is that it can handle

polymer-forming gases and gases containing significant amounts of entrained liq-

uids. Also, the compression chamber is dry so that lubricating oils will not con-

taminate the compressed gases, which is necessary in food and drug-production

processes.

Dynamic Compressors

Dynamic compressors, like fans, are divided into two classes, centrifugal and ax-

ial, according to the direction of gas flow through the machine. A compression

stage for a centrifugal compressor, shown in Figure 5.10, consists of a row of

Copyright © 2003 by Taylor & Francis Group LLC