Page 216 - Chemical process engineering design and economics

P. 216

Compressors, Pumps, and Turbines 199

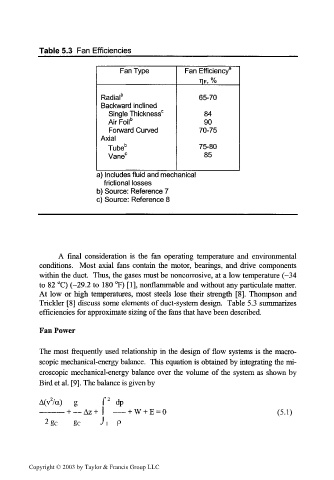

Table 5.3 Fan Efficiencies

Fan Type Fan Efficiency 3

TIP, %

Radial" 65-70

Backward inclined

Single Thickness 0 84

Air Foil" 90

Forward Curved 70-75

Axial

Tube" 75-80

Vane 0 85

a) Includes fluid and mechanical

frictional losses

b) Source: Reference 7

c) Source: Reference 8

A final consideration is the fan operating temperature and environmental

conditions. Most axial fans contain the motor, bearings, and drive components

within the duct. Thus, the gases must be noncorrosive, at a low temperature (-34

to 82 °C) (-29.2 to 180 °F) [1], nonflammable and without any particulate matter.

At low or high temperatures, most steels lose their strength [8]. Thompson and

Trickier [8] discuss some elements of duct-system design. Table 5.3 summarizes

efficiencies for approximate sizing of the fans that have been described.

Fan Power

The most frequently used relationship in the design of flow systems is the macro-

scopic mechanical-energy balance. This equation is obtained by integrating the mi-

croscopic mechanical-energy balance over the volume of the system as shown by

Bird et al. [9]. The balance is given by

2

A(v /a) g f 2 dp

———— + — Az+ I —— + W + E = 0 (5.1)

gc Ji P

2g c

Copyright © 2003 by Taylor & Francis Group LLC