Page 211 - Chemical process engineering design and economics

P. 211

194 Chapter 5

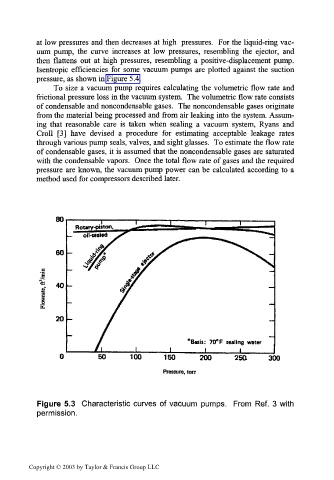

at low pressures and then decreases at high pressures. For the liquid-ring vac-

uum pump, the curve increases at low pressures, resembling the ejector, and

then flattens out at high pressures, resembling a positive-displacement pump.

Isenrropic efficiencies for some vacuum pumps are plotted against the suction

pressure, as shown in Figure 5.4.

To size a vacuum pump requires calculating the volumetric flow rate and

factional pressure loss in the vacuum system. The volumetric flow rate consists

of condensable and noncondensable gases. The noncondensable gases originate

from the material being processed and from air leaking into the system. Assum-

ing that reasonable care is taken when sealing a vacuum system, Ryans and

Croll [3] have devised a procedure for estimating acceptable leakage rates

through various pump seals, valves, and sight glasses. To estimate the flow rate

of condensable gases, it is assumed that the noncondensable gases are saturated

with the condensable vapors. Once the total flow rate of gases and the required

pressure are known, the vacuum pump power can be calculated according to a

method used for compressors described later.

40 -

20 -

100 150 200 250. 300

Pressure, torr

Figure 5.3 Characteristic curves of vacuum pumps. From Ref. 3 with

permission.

Copyright © 2003 by Taylor & Francis Group LLC