Page 207 - Chemical process engineering design and economics

P. 207

190 Chapter 5

VACUUM PUMPS

In the vacuum region, pressures down to 0.00133 bar (0.0193 psia) are of interest

to process engineers for process operations such as distillation, drying and evapo-

ration. Some applications below 0.00132 bar (0.193 psia) are molten metal de-

gassing, molecular distillation, and freeze drying.

The most commonly used vacuum pumps are steam-jet ejectors and several

positive-displacement pumps, which are shown in Figures 5.1 and 5.2. Some of

the characteristics of vacuum pumps are given in Table 5.1. A prime considera-

tion when selecting a vacuum pump is the compatibility of a gas with a seal

fluid. To avoid these problems, there is a trend toward using dry pumps where a

seal fluid or lubricant is not used [60].

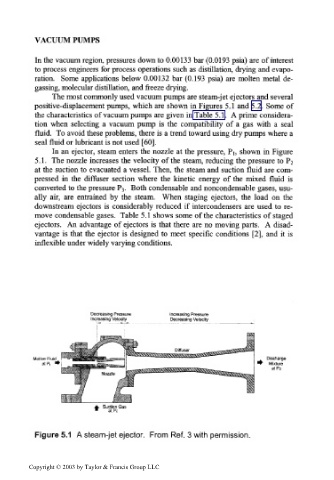

In an ejector, steam enters the nozzle at the pressure, PI, shown in Figure

5.1. The nozzle increases the velocity of the steam, reducing the pressure to P 2

at the suction to evacuated a vessel. Then, the steam and suction fluid are com-

pressed in the diffuser section where the kinetic energy of the mixed fluid is

converted to the pressure P^. Both condensable and noncondensable gases, usu-

ally air, are entrained by the steam. When staging ejectors, the load on the

downstream ejectors is considerably reduced if intercondensers are used to re-

move condensable gases. Table 5.1 shows some of the characteristics of staged

ejectors. An advantage of ejectors is that there are no moving parts. A disad-

vantage is that the ejector is designed to meet specific conditions [2], and it is

inflexible under widely varying conditions.

Decreasing Pressure Increasing Pressure

Increasing Velocity Decreasing Velocity

Motive Fluid Discharge

atP, *> Mixture

atP3

Figure 5.1 A steam-jet ejector. From Ref. 3 with permission.

Copyright © 2003 by Taylor & Francis Group LLC