Page 220 - Chemical process engineering design and economics

P. 220

Compressors, Pumps, and Turbines 203

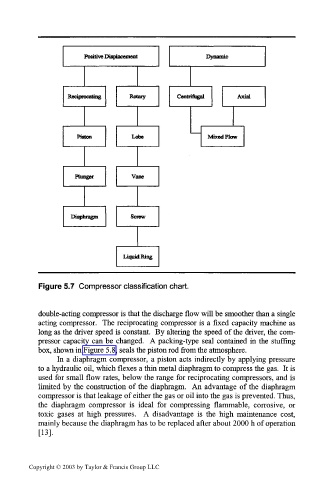

Figure 5.7 Compressor classification chart.

double-acting compressor is that the discharge flow will be smoother than a single

acting compressor. The reciprocating compressor is a fixed capacity machine as

long as the driver speed is constant. By altering the speed of the driver, the com-

pressor capacity can be changed. A packing-type seal contained in the stuffing

box, shown in Figure 5.8, seals the piston rod from the atmosphere.

In a diaphragm compressor, a piston acts indirectly by applying pressure

to a hydraulic oil, which flexes a thin metal diaphragm to compress the gas. It is

used for small flow rates, below the range for reciprocating compressors, and is

limited by the construction of the diaphragm. An advantage of the diaphragm

compressor is that leakage of either the gas or oil into the gas is prevented. Thus,

the diaphragm compressor is ideal for compressing flammable, corrosive, or

toxic gases at high pressures. A disadvantage is the high maintenance cost,

mainly because the diaphragm has to be replaced after about 2000 h of operation

[13].

Copyright © 2003 by Taylor & Francis Group LLC