Page 267 - Chemical process engineering design and economics

P. 267

Compressors, Pumps, and Turbines 247

Ideal

i

Actual

T

Slip

Pressure

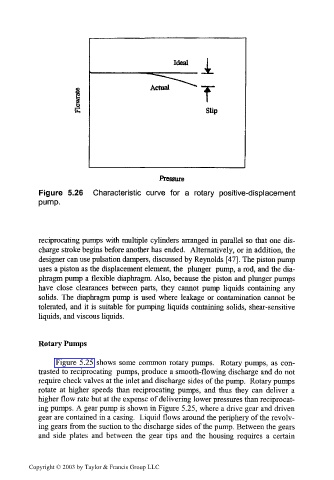

Figure 5.26 Characteristic curve for a rotary positive-displacement

pump.

reciprocating pumps with multiple cylinders arranged in parallel so that one dis-

charge stroke begins before another has ended. Alternatively, or in addition, the

designer can use pulsation dampers, discussed by Reynolds [47]. The piston pump

uses a piston as the displacement element, the plunger pump, a rod, and the dia-

phragm pump a flexible diaphragm. Also, because the piston and plunger pumps

have close clearances between parts, they cannot pump liquids containing any

solids. The diaphragm pump is used where leakage or contamination cannot be

tolerated, and it is suitable for pumping liquids containing solids, shear-sensitive

liquids, and viscous liquids.

Rotary Pumps

Figure 5.25 shows some common rotary pumps. Rotary pumps, as con-

trasted to reciprocating pumps, produce a smooth-flowing discharge and do not

require check valves at the inlet and discharge sides of the pump. Rotary pumps

rotate at higher speeds than reciprocating pumps, and thus they can deliver a

higher flow rate but at the expense of delivering lower pressures than reciprocat-

ing pumps. A gear pump is shown in Figure 5.25, where a drive gear and driven

gear are contained in a casing. Liquid flows around the periphery of the revolv-

ing gears from the suction to the discharge sides of the pump. Between the gears

and side plates and between the gear tips and the housing requires a certain

Copyright © 2003 by Taylor & Francis Group LLC