Page 264 - Chemical process engineering design and economics

P. 264

244 Chapter 5

cause of this characteristic of positive-displacement pumps, if a valve, located on

the discharge side of the pump, is used to vary the flow rate, then, the discharged

pressure must be controlled. A variable-speed drive could also be used to vary the

flow rate. Generally, positive-displacement pumps are employed where it is re-

quired to deliver low flow rates at high pressures. If high flow rates at high pres-

sures are required, then the pumps are installed in parallel. To develop high pres-

sures requires close clearances between the moving parts to minimize leakage, but

close clearances means that the pump must move at slower speeds to avoid ex-

cessive wear. Thus, pumps designed to develop high pressures are forced to de-

liver low flow rates. On the other hand, pumps designed to deliver high flow rates

usually cannot develop high pressures.

Positive-displacement pumps are self priming, which is the ability of a

pump to lift liquids from a level below the center line of the pump. This charac-

teristic of positive-displacement pumps is attributed to the tight seal between the

discharge and suction sides of the pump. Thus, at startup air is compressed and

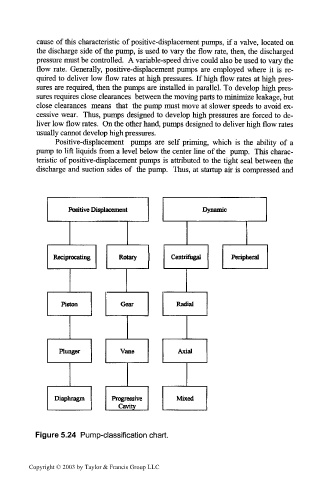

Figure 5.24 Pump-classification chart.

Copyright © 2003 by Taylor & Francis Group LLC