Page 261 - Chemical process engineering design and economics

P. 261

Compressors, Pumps, and Turbines 241

ration of air into oxygen and nitrogen, recovery of condensable hydrocarbons from

natural gas, liquefaction of gases, and energy recovery from high pressure gas

streams. After conducting chemical reactions at high pressures, the pressure of the

effluent stream must be eventually reduced. For example, in the process for syn-

thesizing methanol, the purge gas from the synthesis loop is used as a fuel at 3 to 4

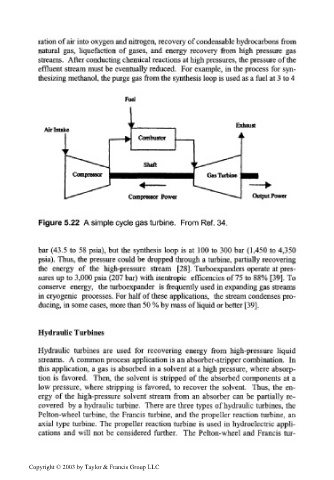

Fuel

Exhaust

Air Intake

Compressor Power Output Power

Figure 5.22 A simple cycle gas turbine. From Ref. 34.

bar (43.5 to 58 psia), but the synthesis loop is at 100 to 300 bar (1,450 to 4,350

psia). Thus, the pressure could be dropped through a turbine, partially recovering

the energy of the high-pressure stream [28]. Turboexpanders operate at pres-

sures up to 3,000 psia (207 bar) with isentropic efficencies of 75 to 88% [39]. To

conserve energy, the turboexpander is frequently used in expanding gas streams

in cryogenic processes. For half of these applications, the stream condenses pro-

ducing, in some cases, more than 50 % by mass of liquid or better [39].

Hydraulic Turbines

Hydraulic turbines are used for recovering energy from high-pressure liquid

streams. A common process application is an absorber-stripper combination. In

this application, a gas is absorbed in a solvent at a high pressure, where absorp-

tion is favored. Then, the solvent is stripped of the absorbed components at a

low pressure, where stripping is favored, to recover the solvent. Thus, the en-

ergy of the high-pressure solvent stream from an absorber can be partially re-

covered by a hydraulic turbine. There are three types of hydraulic turbines, the

Pelton-wheel turbine, the Francis turbine, and the propeller reaction turbine, an

axial type turbine. The propeller reaction turbine is used in hydroelectric appli-

cations and will not be considered further. The Pelton-wheel and Francis tur-

Copyright © 2003 by Taylor & Francis Group LLC