Page 265 - Chemical process engineering design and economics

P. 265

Compressors, Pumps, and Turbines 245

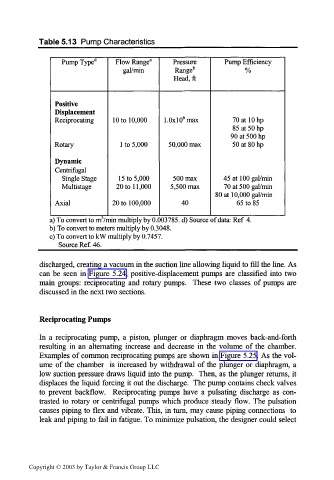

Table 5.13 Pump Characteristics

Pump Type" Flow Range 3 Pressure Pump Efficiency

gal/min Range b %

Head, ft

Positive

Displacement

s

Reciprocating 10 to 10,000 1.0xlO max 70 at 10 hp

85 at 50 hp

90 at 500 hp

Rotary 1 to 5,000 50,000 max 50 at 80 hp

Dynamic

Centrifugal

Single Stage 15 to 5,000 500 max 45 at 100 gal/min

Multistage 20 to 11, 000 5,500 max 70 at 500 gal/min

80 at 10,000 gal/min

Axial 20 to 100,000 40 65 to 85

a) To convert to rrrVmin multiply by 0.003785. d) Source of data: Ref 4.

b) To convert to meters multiply by 0.3048.

c) To convert to kW multiply by 0.7457.

Source Ref. 46.

discharged, creating a vacuum in the suction line allowing liquid to fill the line. As

can be seen in Figure 5.24, positive-displacement pumps are classified into two

main groups: reciprocating and rotary pumps. These two classes of pumps are

discussed in the next two sections.

Reciprocating Pumps

In a reciprocating pump, a piston, plunger or diaphragm moves back-and-forth

resulting in an alternating increase and decrease in the volume of the chamber.

Examples of common reciprocating pumps are shown in Figure 5.25. As the vol-

ume of the chamber is increased by withdrawal of the plunger or diaphragm, a

low suction pressure draws liquid into the pump. Then, as the plunger returns, it

displaces the liquid forcing it out the discharge. The pump contains check valves

to prevent backflow. Reciprocating pumps have a pulsating discharge as con-

trasted to rotary or centrifugal pumps which produce steady flow. The pulsation

causes piping to flex and vibrate. This, in turn, may cause piping connections to

leak and piping to fail in fatigue. To minimize pulsation, the designer could select

Copyright © 2003 by Taylor & Francis Group LLC