Page 262 - Chemical process engineering design and economics

P. 262

242 Chapter 5

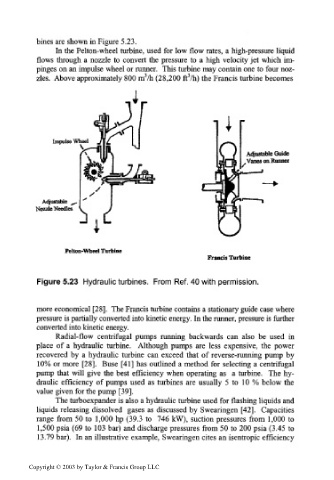

bines are shown in Figure 5.23.

In the Pelton-wheel turbine, used for low flow rates, a high-pressure liquid

flows through a nozzle to convert the pressure to a high velocity jet which im-

pinges on an impulse wheel or runner. This turbine may contain one to four noz-

3

3

zles. Above approximately 800 m /h (28,200 ft /h) the Francis turbine becomes

Impulse Wheel

Adjustable Guide

, Vanes on Runner

Adjustable __

Nozzle Needles

Pelton-Wheel Turbine

Francis Turbine

Figure 5.23 Hydraulic turbines. From Ref. 40 with permission.

more economical [28]. The Francis turbine contains a stationary guide case where

pressure is partially converted into kinetic energy. In the runner, pressure is further

converted into kinetic energy.

Radial-flow centrifugal pumps running backwards can also be used in

place of a hydraulic turbine. Although pumps are less expensive, the power

recovered by a hydraulic turbine can exceed that of reverse-running pump by

10% or more [28]. Buse [41] has outlined a method for selecting a centrifugal

pump that will give the best efficiency when operating as a turbine. The hy-

draulic efficiency of pumps used as turbines are usually 5 to 10 % below the

value given for the pump [39].

The turboexpander is also a hydraulic turbine used for flashing liquids and

liquids releasing dissolved gases as discussed by Swearingen [42]. Capacities

range from 50 to 1,000 hp (39.3 to 746 kW), suction pressures from 1,000 to

1,500 psia (69 to 103 bar) and discharge pressures from 50 to 200 psia (3.45 to

13.79 bar). In an illustrative example, Swearingen cites an isentropic efficiency

Copyright © 2003 by Taylor & Francis Group LLC