Page 277 - Chemical process engineering design and economics

P. 277

256 Chapter 5

Table 5.16 Approximate Pump-Sizing Calculation Procedure_______

1. Define the flow system, i.e., locate points 1 and 2. The pressures pi and p will

2

be known at these points.

2. Locate the process equipment according to the rules-of-thumb listed in Table

5.14.

3. Estimate z t and z 2.

4. Estimate the frictional pressure losses E and E using the rules-of-thumb given

s D

in Table 5.15.

5. Calculate the pump work from Equation 5.48.

6. Calculate the pump shaft horsepower using Equation 5.49 and the pump effi-

ciencies given in Table 5.13.

7. Calculate the electric-motor horsepower using the motor efficiency given in

Table 5.9.

8. Select a standard electric-motor horsepower using Table 5.10 to obtain ap-

proximately a 10% safety factor.

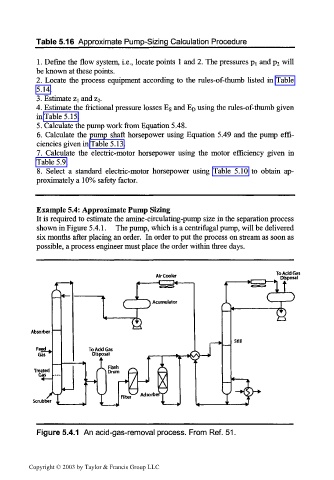

Example 5.4: Approximate Pump Sizing

It is required to estimate the amine-circulating-pump size in the separation process

shown in Figure 5.4.1. The pump, which is a centrifugal pump, will be delivered

six months after placing an order. In order to put the process on stream as soon as

possible, a process engineer must place the order within three days.

Air Cooler To Add Gas

Disposal

Absorber

Scrubber

Figure 5.4.1 An acid-gas-removal process. From Ref. 51.

Copyright © 2003 by Taylor & Francis Group LLC