Page 278 - Chemical process engineering design and economics

P. 278

Compressors, Pumps, and Turbines 257

Process Description

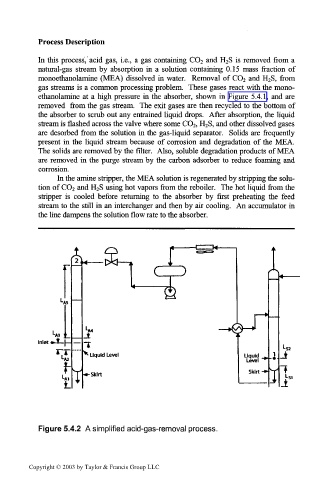

In this process, acid gas, i.e., a gas containing CO 2 and H 2S is removed from a

natural-gas stream by absorption in a solution containing 0.15 mass fraction of

monoethanolamine (MEA) dissolved in water. Removal of CO 2 and H 2S, from

gas streams is a common processing problem. These gases react with the mono-

ethanolamine at a high pressure in the absorber, shown in Figure 5.4.1, and are

removed from the gas stream. The exit gases are then recycled to the bottom of

the absorber to scrub out any entrained liquid drops. After absorption, the liquid

stream is flashed across the valve where some CO 2, H 2S, and other dissolved gases

are desorbed from the solution in the gas-liquid separator. Solids are frequently

present in the liquid stream because of corrosion and degradation of the MEA.

The solids are removed by the filter. Also, soluble degradation products of MEA

are removed in the purge stream by the carbon adsorber to reduce foaming and

corrosion.

In the amine stripper, the MEA solution is regenerated by stripping the solu-

tion of CO 2 and H 2S using hot vapors from the reboiler. The hot liquid from the

stripper is cooled before returning to the absorber by first preheating the feed

stream to the still in an interchanger and then by air cooling. An accumulator in

the line dampens the solution flow rate to the absorber.

A

Inlet *-*-[- —

Figure 5.4.2 A simplified acid-gas-removal process.

Copyright © 2003 by Taylor & Francis Group LLC