Page 327 - Chemical process engineering design and economics

P. 327

306 Chapter 6

separating the air and filtrate, the filtrate is pumped out for further processing, and

the air is removed by the vacuum pump. The air then flows into the separator-

silencer. The separator-silencer is another gas-liquid separator or knock-out drum.

These drums are for small amounts of liquid entrained in the entering gas. In addi-

tion, the silencer attenuates the noise produced by the vacuum pump. An air com-

pressor provides air to push the filter cloth against the scraper for cake removal.

After the compressor is a knock-out drum for removing water drops produced by

cooling of the compressed air. Other auxiliary equipment may be added to the

filtration system, depending on the composition of the slurry. For example, if the

liquid is an organic solvent, a component separator, such as an absorber, will be

necessary to remove the solvent from the exhaust air. Also, if it is necessary to

keep the filtrate and wash water separate, two receivers are used.

To obtain a formula for sizing a rotary-drum filter, the mechanism of liquid

flow through a porous medium must be considered. As the filter drum rotates

through the slurry tank, a porous solid deposits on the surface of the drum, increas-

ing the resistance to liquid flow. The surface of the filter cake is at atmospheric

pressure. If it is assumed that the pressure downstream of the filter medium is

constant (created by a vacuum pump), then the pressure drop across the filter cake

and medium is constant. As the filter cake thickens, the liquid flow rate decreases

because of the increasing resistance to flow.

The starting point for deriving a formula to calculate the filtration area is the

Kozeny-Carmen equation for flow through porous media. The flow, which is

laminar, follows a tortuous path through the cake. The Kozeny-Carmen equation,

for a differential cake thickness, is

2

dP 4.17s uv s (l-s) 2

—— = ——————————— (6. 17)

dx E 2

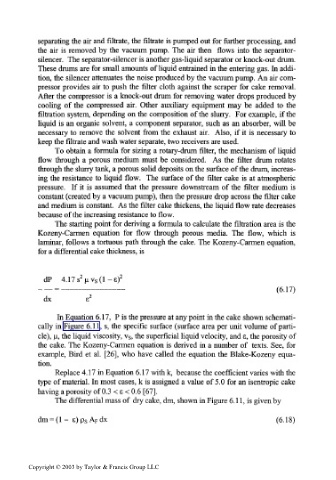

In Equation 6.17, P is the pressure at any point in the cake shown schemati-

cally in Figure 6.11, s, the specific surface (surface area per unit volume of parti-

cle), u, the liquid viscosity, vs, the superficial liquid velocity, and s, the porosity of

the cake. The Kozeny-Carmen equation is derived in a number of texts. See, for

example, Bird et al. [26], who have called the equation the Blake-Kozeny equa-

tion.

Replace 4.17 in Equation 6.17 with k, because the coefficient varies with the

type of material. In most cases, k is assigned a value of 5.0 for an isentropic cake

having a porosity of 0.3 < s < 0.6 [67].

The differential mass of dry cake, dm, shown in Figure 6.11, is given by

dm = (l- e)p s A F dx (6.18)

Copyright © 2003 by Taylor & Francis Group LLC