Page 326 - Chemical process engineering design and economics

P. 326

Separator Design 305

is usually divided into 12 to 24 longitudinal compartments [25], depending on the

drum diameter. Each compartment contains channels for collecting liquid that

flows into filtrate piping, which leads to the filter valve at one end of the drum. A

vacuum can be applied separately to each compartment. The drum is partially

submerged in a slurry tank, which contains an agitator to prevent solids from set-

tling. Usually, the slurry tank is designed to submerge about 40% of the drum

area, but the maximum effective submerged filter area that can be subjected to

vacuum is about 37.5%. As the drum rotates, each compartment is connected to

an external system by the filter valve to apply vacuum, to collect filtrate, to collect

wash water, or to apply air pressure to assist in removing solids from the drum.

The operation of a rotary-drum filter can be followed by examining Figure

6.9. In the cake-forming zone, slurry is drawn from the slurry tank onto the drum

by a vacuum, depositing solids on the drum. After leaving this zone, the cake is

dewatered, washed, if it is necessary, and then dewatered again before being dis-

charged. In one method of cake removal, compressed air pushes the filter cloth

against a knife that scrapes the cake from the cloth. The cake could also be re-

moved by a roll, string or belt, depending on the cake thickness.

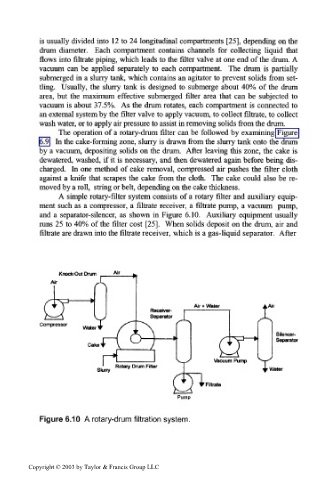

A simple rotary-filter system consists of a rotary filter and auxiliary equip-

ment such as a compressor, a filtrate receiver, a filtrate pump, a vacuum pump,

and a separator-silencer, as shown in Figure 6.10. Auxiliary equipment usually

runs 25 to 40% of the filter cost [25]. When solids deposit on the drum, air and

filtrate are drawn into the filtrate receiver, which is a gas-liquid separator. After

Knock-Out Drum Air

Compressor

Slurry ^r Water

Filtrate

Pump

Figure 6.10 A rotary-drum filtration system.

Copyright © 2003 by Taylor & Francis Group LLC