Page 429 - Chemical process engineering design and economics

P. 429

Reactor Design 409

and

K P = 0.027 exp [ 0.21 (T - 773)]

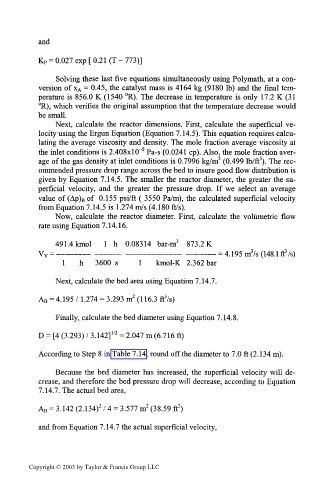

Solving these last five equations simultaneously using Polymath, at a con-

version of X A = 0.45, the catalyst mass is 4164 kg (9180 Ib) and the final tem-

perature is 856.0 K (1540 °R). The decrease in temperature is only 17.2 K (31

°R), which verifies the original assumption that the temperature decrease would

be small.

Next, calculate the reactor dimensions. First, calculate the superficial ve-

locity using the Ergun Equation (Equation 7.14.5). This equation requires calcu-

lating the average viscosity and density. The mole fraction average viscosity at

5

the inlet conditions is 2.408xlO~ Pa-s (0.0241 cp). Also, the mole fraction aver-

3

3

age of the gas density at inlet conditions is 0.7996 kg/m (0.499 lb/ft ). The rec-

ommended pressure drop range across the bed to insure good flow distribution is

given by Equation 7.14.5. The smaller the reactor diameter, the greater the su-

perficial velocity, and the greater the pressure drop. If we select an average

value of (Ap) B of 0.155 psi/ft ( 3550 Pa/m), the calculated superficial velocity

from Equation 7.14.5 is 1.274 m/s (4.180 ft/s).

Now, calculate the reactor diameter. First, calculate the volumetric flow

rate using Equation 7.14.16.

491.4 kmol 1 h 0.08314 bar-m 3 873.2 K

3

V V v — ————————— — ________ __________________ __ ——————— —A T.1I7_> 111 fa ^Ito.l 1L lo)

1Q^ m /o HAS 1 ft /a\

3

1 h 3600 s 1 kmol-K 2.362 bar

Next, calculate the bed area using Equation 7.14.7.

2

A B = 4.195 /1.274 = 3.293 m (116.3 ffVs)

Finally, calculate the bed diameter using Equation 7.14.8.

1/2

D = [4 (3.293) / 3.142] = 2.047 m (6.716 ft)

According to Step 8 in Table 7.14, round off the diameter to 7.0 ft (2.134 m).

Because the bed diameter has increased, the superficial velocity will de-

crease, and therefore the bed pressure drop will decrease, according to Equation

7.14.7. The actual bed area,

2

2

2

A B = 3.142 (2.134) / 4 = 3.577 m (38.59 ft )

and from Equation 7.14.7 the actual superficial velocity,

Copyright © 2003 by Taylor & Francis Group LLC