Page 426 - Chemical process engineering design and economics

P. 426

406 Chapter/

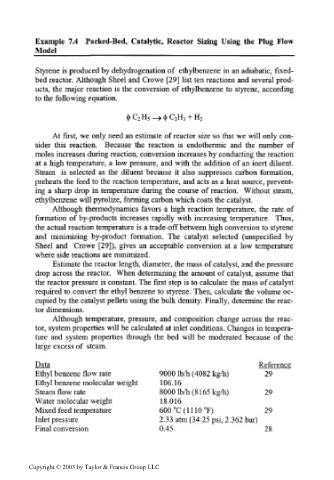

Example 7.4 Packed-Bed, Catalytic, Reactor Sizing Using the Plug Flow

Model _________________________________________

Styrene is produced by dehydrogenation of ethylbenzene in an adiabatic, fixed-

bed reactor. Although Sheel and Crowe [29] list ten reactions and several prod-

ucts, the major reaction is the conversion of ethylbenzene to styrene, according

to the following equation.

At first, we only need an estimate of reactor size so that we will only con-

sider this reaction. Because the reaction is endothermic and the number of

moles increases during reaction, conversion increases by conducting the reaction

at a high temperature, a low pressure, and with the addition of an inert diluent.

Steam is selected as the diluent because it also suppresses carbon formation,

preheats the feed to the reaction temperature, and acts as a heat source, prevent-

ing a sharp drop in temperature during the course of reaction. Without steam,

ethylbenzene will pyrolize, forming carbon which coats the catalyst.

Although thermodynamics favors a high reaction temperature, the rate of

formation of by-products increases rapidly with increasing temperature. Thus,

the actual reaction temperature is a trade-off between high conversion to styrene

and minimizing by-product formation. The catalyst selected (unspecified by

Sheel and Crowe [29]), gives an acceptable conversion at a low temperature

where side reactions are minimized.

Estimate the reactor length, diameter, the mass of catalyst, and the pressure

drop across the reactor. When determining the amount of catalyst, assume that

the reactor pressure is constant. The first step is to calculate the mass of catalyst

required to convert the ethyl benzene to styrene. Then, calculate the volume oc-

cupied by the catalyst pellets using the bulk density. Finally, determine the reac-

tor dimensions.

Although temperature, pressure, and composition change across the reac-

tor, system properties will be calculated at inlet conditions. Changes in tempera-

ture and system properties through the bed will be moderated because of the

large excess of steam.

Data Reference

Ethyl benzene flow rate 9000 Ib/h (4082 kg/h) 29

Ethyl benzene molecular weight 1 06. 1 6

Steam flow rate 8000 Ib/h (8 1 65 kg/h) 29

Water molecular weight 18.016

Mixed feed temperature 600 °C ( 1 1 1 0 °F) 29

Inlet pressure 2.33 arm (34.25 psi, 2.362 bar)

Final conversion 0.45 28

Copyright © 2003 by Taylor & Francis Group LLC