Page 422 - Chemical process engineering design and economics

P. 422

402 Chapter 7

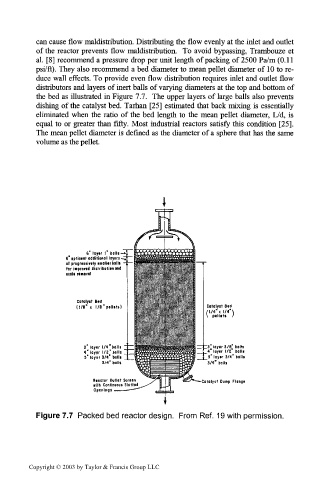

can cause flow maldistribution. Distributing the flow evenly at the inlet and outlet

of the reactor prevents flow maldistribution. To avoid bypassing, Trambouze et

al. [8] recommend a pressure drop per unit length of packing of 2500 Pa/m (0.11

psi/ft). They also recommend a bed diameter to mean pellet diameter of 10 to re-

duce wall effects. To provide even flow distribution requires inlet and outlet flow

distributors and layers of inert balls of varying diameters at the top and bottom of

the bed as illustrated in Figure 7.7. The upper layers of large balls also prevents

dishing of the catalyst bed. Tarhan [25] estimated that back mixing is essentially

eliminated when the ratio of the bed length to the mean pellet diameter, L/d, is

equal to or greater than fifty. Most industrial reactors satisfy this condition [25].

The mean pellet diameter is defined as the diameter of a sphere that has the same

volume as the pellet.

6'loyir l" belli-

6" optional additional layers,

of progressively smaller balls

for iiepwed distribution and

icalf removal

cotalyit Beil

H/8" « l/8'pellsts) Catalyst Bed

M/4"< 1/4" \

\ pellets I

3" layer l/4"bolls " ~ ~ 13 loyer 3/B bolls

4"loyer 1/z" tolls _ 4 loyer 1/2 tolls

5" loyer 5/4" balls } 5" layer 3/4" balls

3/4" balls 3/4" bolls

Reactor Outlet Screen Catalyst Dump Flange

with Continuous Slotted

Openings

Figure 7.7 Packed bed reactor design. From Ref. 19 with permission.

Copyright © 2003 by Taylor & Francis Group LLC