Page 423 - Chemical process engineering design and economics

P. 423

Reactor Design 403

The third and fourth condition are fulfilled by Tarhan [25]. "Axial dispersion is

fundamentally local backmixing of reactants and products in the axial, or longi-

tudinal direction in the small interstices of the packed bed, which is due to mo-

lecular diffusion, convection, and turbulence. Axial dispersion has been shown

to be negligible in fixed-bed gas reactors. The fourth condition (no radial dis-

persion) can be met if the flow pattern through the bed already meets the second

condition. If the flow velocity in the axial direction is constant through the en-

tire cross section and if the reactor is well insulated (first condition), there can

be no radial dispersion to speak of in gas reactors. Thus, the one-dimensional

adiabatic reactor model may be actualized without great difficulties."

The pseudo-homogeneous assumption means that both the solid and fluid

phases are are considered a single phase. Therefore, we avoid considering mass

and heat transfer from and to the catalytic pellets. This model assumes that the

component concentrations and the temperature in the pellets are the same as those

in the fluid phase. This assumption is approximated when the catalyst pellet is

small and mass and heat transfer between the pellets and the fluid phase are rapid.

The reaction rate for this model, called the global reaction rate, includes heat and

mass transfer. If heat and mass transfer are made insignificant, then the reaction

rate is called the intrinsic reaction rate.

Equations for sizing packed-bed reactors are listed in Tablet 7.14, and a

calculating procedure is outlined in Table 7.15. The procedure for calculating

the reactor dimensions is similar to that given for the space-velocity method. In

this procedure, however, the calculation of the reaction volume is more accurate

than the method using space velocity. First, the reaction volume for adiabatic

operation is calculated by solving the mole and energy balances along with the

kinetic equation. Also, instead of using a rule-of-thumb, we use the Ergun equa-

tion, Equation 7.14.5 in Table 7.14, derive by Bird et al. [32], to calculate the

superficial velocity in the bed. To calculate the velocity, fix the pressure drop

across the bed, (Ap) B to insure good flow distribution as given in Equation

7.14.5. This equation requires calculating the average viscosity and density of a

gas mixture, as given by Equations 7.14.14 and 7.14.15. Pure component vis-

cosities are estimated using the corresponding state approach outlined by Bird et

al. [32].

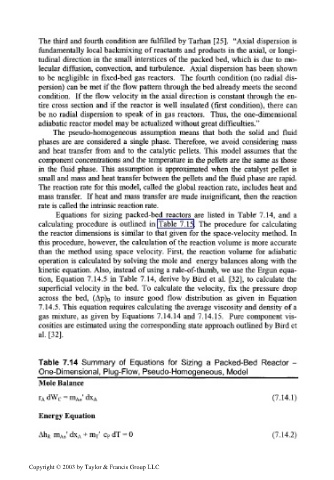

Table 7.14 Summary of Equations for Sizing a Packed-Bed Reactor -

One-Dimensional, Plug-Flow, Pseudo-Homogeneous, Model_______

Mole Balance

r A dW c = m Ao'dx A (7.14.1)

Energy Equation

Ah R m Ao' dx A + m T' C P dT = 0 (7.14.2)

Copyright © 2003 by Taylor & Francis Group LLC