Page 425 - Chemical process engineering design and economics

P. 425

Reactor Design 405

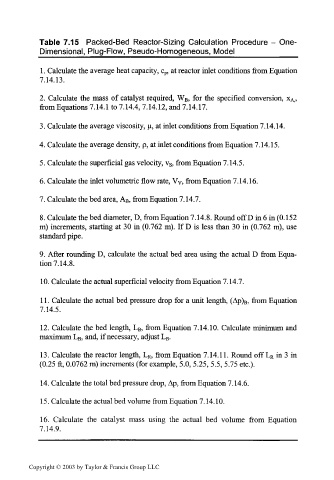

Table 7.15 Packed-Bed Reactor-Sizing Calculation Procedure - One-

Dimensional, Plug-Flow, Pseudo-Homogeneous, Model_________

1. Calculate the average heat capacity, c, at reactor inlet conditions from Equation

p

7.14.13.

2. Calculate the mass of catalyst required, WB, for the specified conversion, XA,,

from Equations 7.14.1 to 7.14.4, 7.14.12, and 7.14.17.

3. Calculate the average viscosity, (j, at inlet conditions from Equation 7.14.14.

4. Calculate the average density, p, at inlet conditions from Equation 7.14.15.

5. Calculate the superficial gas velocity, v s, from Equation 7.14.5.

6. Calculate the inlet volumetric flow rate, V v, from Equation 7.14.16.

7. Calculate the bed area, A B, from Equation 7.14.7.

8. Calculate the bed diameter, D, from Equation 7.14.8. Round off D in 6 in (0.152

m) increments, starting at 30 in (0.762 m). If D is less than 30 in (0.762 m), use

standard pipe.

9. After rounding D, calculate the actual bed area using the actual D from Equa-

tion 7.14.8.

10. Calculate the actual superficial velocity from Equation 7.14.7.

11. Calculate the actual bed pressure drop for a unit length, (Ap), from Equation

B

7.14.5.

12. Calculate the bed length, L, from Equation 7.14.10. Calculate minimum and

B

maximum L B, and, if necessary, adjust L B.

13. Calculate the reactor length, L, from Equation 7.14.11. Round off L in 3 in

R R

(0.25 ft, 0.0762 m) increments (for example, 5.0, 5.25, 5.5, 5.75 etc.).

14. Calculate the total bed pressure drop, Ap, from Equation 7.14.6.

15. Calculate the actual bed volume from Equation 7.14.10.

16. Calculate the catalyst mass using the actual bed volume from Equation

7.14.9.

Copyright © 2003 by Taylor & Francis Group LLC