Page 156 - Chiral Separation Techniques

P. 156

134 5 Membranes in Chiral Separations

a) b)

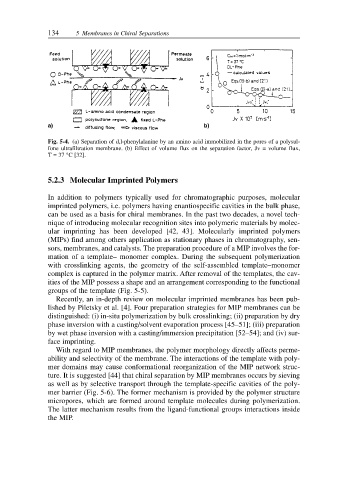

Fig. 5-4. (a) Separation of d,l-phenylalanine by an amino acid immobilized in the pores of a polysul-

fone ultrafiltration membrane. (b) Effect of volume flux on the separation factor, Jv = volume flux,

T = 37 °C [32].

5.2.3 Molecular Imprinted Polymers

In addition to polymers typically used for chromatographic purposes, molecular

imprinted polymers, i.e. polymers having enantiospecific cavities in the bulk phase,

can be used as a basis for chiral membranes. In the past two decades, a novel tech-

nique of introducing molecular recognition sites into polymeric materials by molec-

ular imprinting has been developed [42, 43]. Molecularly imprinted polymers

(MIPs) find among others application as stationary phases in chromatography, sen-

sors, membranes, and catalysts. The preparation procedure of a MIP involves the for-

mation of a template– monomer complex. During the subsequent polymerization

with crosslinking agents, the geometry of the self-assembled template–monomer

complex is captured in the polymer matrix. After removal of the templates, the cav-

ities of the MIP possess a shape and an arrangement corresponding to the functional

groups of the template (Fig. 5-5).

Recently, an in-depth review on molecular imprinted membranes has been pub-

lished by Piletsky et al. [4]. Four preparation strategies for MIP membranes can be

distinguished: (i) in-situ polymerization by bulk crosslinking; (ii) preparation by dry

phase inversion with a casting/solvent evaporation process [45–51]; (iii) preparation

by wet phase inversion with a casting/immersion precipitation [52–54]; and (iv) sur-

face imprinting.

With regard to MIP membranes, the polymer morphology directly affects perme-

ability and selectivity of the membrane. The interactions of the template with poly-

mer domains may cause conformational reorganization of the MIP network struc-

ture. It is suggested [44] that chiral separation by MIP membranes occurs by sieving

as well as by selective transport through the template-specific cavities of the poly-

mer barrier (Fig. 5-6). The former mechanism is provided by the polymer structure

micropores, which are formed around template molecules during polymerization.

The latter mechanism results from the ligand-functional groups interactions inside

the MIP.