Page 297 - Chiral Separation Techniques

P. 297

276 10 The Use of SMB for the Manufacture of Enantiopure Drug Substances: From …

tion of cGMP compliance for the manufacture of enantiopure drug substances to the

SMB process.

10.5.1.2 Solvent Recovery

The draft document address the issue of solvent recovered from a process and the

use of these solvents in the same process or reused for different processes. It requires

that recovery procedures be validated to ensure cross-contamination between recov-

ered solvents and monitoring of the solvent composition at suitable intervals during

the process.

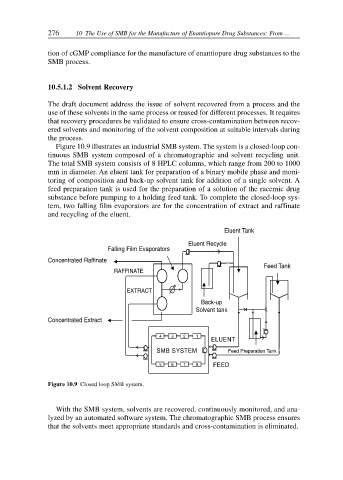

Figure 10.9 illustrates an industrial SMB system. The system is a closed-loop con-

tinuous SMB system composed of a chromatographic and solvent recycling unit.

The total SMB system consists of 8 HPLC columns, which range from 200 to 1000

mm in diameter. An eluent tank for preparation of a binary mobile phase and moni-

toring of composition and back-up solvent tank for addition of a single solvent. A

feed preparation tank is used for the preparation of a solution of the racemic drug

substance before pumping to a holding feed tank. To complete the closed-loop sys-

tem, two falling film evaporators are for the concentration of extract and raffinate

and recycling of the eluent.

Eluent Tank

Eluent Recycle

Falling Film Evaporators

Concentrated Raffinate

Feed Tank

RAFFINATE

EXTRACT

Back-up

Solvent tank

Concentrated Extract

4 3 2 1

ELUENT

SMB SYSTEM Feed Preparation Tank

5 6 7 8 FEED

Figure 10.9 Closed loop SMB system.

With the SMB system, solvents are recovered, continuously monitored, and ana-

lyzed by an automated software system. The chromatographic SMB process ensures

that the solvents meet appropriate standards and cross-contamination is eliminated.