Page 409 - Compression Machinery for Oil and Gas

P. 409

388 SECTION III Applications

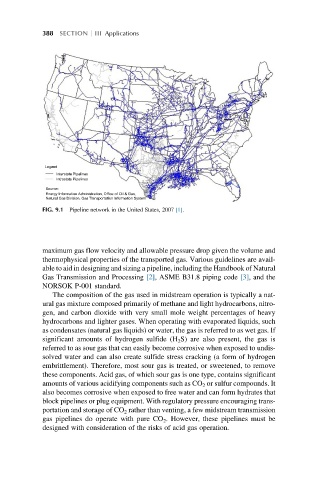

Legend

Interstate Pipelines

Intrastate Pipelines

Source:

Energy Information Administration, Office of Oil & Gas,

Natural Gas Division, Gas Transportation Information System

FIG. 9.1 Pipeline network in the United States, 2007 [1].

maximum gas flow velocity and allowable pressure drop given the volume and

thermophysical properties of the transported gas. Various guidelines are avail-

able to aid in designing and sizing a pipeline, including the Handbook of Natural

Gas Transmission and Processing [2], ASME B31.8 piping code [3], and the

NORSOK P-001 standard.

The composition of the gas used in midstream operation is typically a nat-

ural gas mixture composed primarily of methane and light hydrocarbons, nitro-

gen, and carbon dioxide with very small mole weight percentages of heavy

hydrocarbons and lighter gases. When operating with evaporated liquids, such

as condensates (natural gas liquids) or water, the gas is referred to as wet gas. If

significant amounts of hydrogen sulfide (H 2 S) are also present, the gas is

referred to as sour gas that can easily become corrosive when exposed to undis-

solved water and can also create sulfide stress cracking (a form of hydrogen

embrittlement). Therefore, most sour gas is treated, or sweetened, to remove

these components. Acid gas, of which sour gas is one type, contains significant

amounts of various acidifying components such as CO 2 or sulfur compounds. It

also becomes corrosive when exposed to free water and can form hydrates that

block pipelines or plug equipment. With regulatory pressure encouraging trans-

portation and storage of CO 2 rather than venting, a few midstream transmission

gas pipelines do operate with pure CO 2 . However, these pipelines must be

designed with consideration of the risks of acid gas operation.