Page 404 - Compression Machinery for Oil and Gas

P. 404

382 SECTION III Applications

TABLE 8.3 Typical Characteristics for Reinjection Applications

Pressure Suction pressure varies greatly, typically 0.3–0.7MPa but higher for

high discharge pressures. Discharge pressures typically 14–82MPa

Temperature 303–308K suction to 449–463K discharge

Fluids Natural gas, CO 2 , sour/acid gas

Compression 1–20MW

power

Typical Centrifugal compressor (typically barrel compressor for high

machinery discharge pressures)

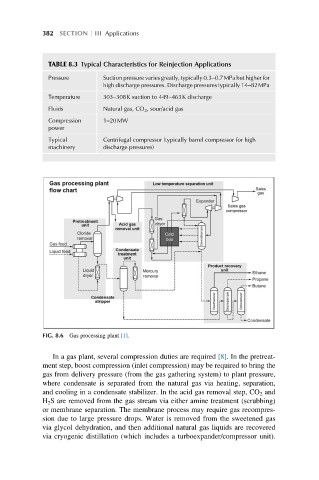

FIG. 8.6 Gas processing plant [1].

In a gas plant, several compression duties are required [8]. In the pretreat-

ment step, boost compression (inlet compression) may be required to bring the

gas from delivery pressure (from the gas gathering system) to plant pressure,

where condensate is separated from the natural gas via heating, separation,

and cooling in a condensate stabilizer. In the acid gas removal step, CO 2 and

H 2 S are removed from the gas stream via either amine treatment (scrubbing)

or membrane separation. The membrane process may require gas recompres-

sion due to large pressure drops. Water is removed from the sweetened gas

via glycol dehydration, and then additional natural gas liquids are recovered

via cryogenic distillation (which includes a turboexpander/compressor unit).