Page 403 - Compression Machinery for Oil and Gas

P. 403

Upstream Compression Applications Chapter 8 381

Production well

Injection well

Drive Miscible Oil

Water CO 2

CO 2

water zone bank

and Oil expands and moves

Injected CO 2

CO 2

encounters trapped oil oil mix towards producing well

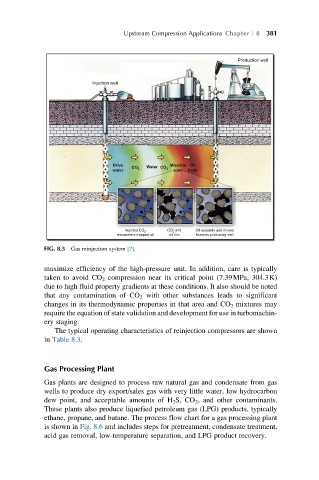

FIG. 8.5 Gas reinjection system [7].

maximize efficiency of the high-pressure unit. In addition, care is typically

taken to avoid CO 2 compression near its critical point (7.39MPa, 304.3K)

due to high fluid property gradients at these conditions. It also should be noted

that any contamination of CO 2 with other substances leads to significant

changes in its thermodynamic properties in that area and CO 2 mixtures may

require the equation of state validation and development for use in turbomachin-

ery staging.

The typical operating characteristics of reinjection compressors are shown

in Table 8.3.

Gas Processing Plant

Gas plants are designed to process raw natural gas and condensate from gas

wells to produce dry export/sales gas with very little water, low hydrocarbon

dew point, and acceptable amounts of H 2 S, CO 2 , and other contaminants.

These plants also produce liquefied petroleum gas (LPG) products, typically

ethane, propane, and butane. The process flow chart for a gas processing plant

is shown in Fig. 8.6 and includes steps for pretreatment, condensate treatment,

acid gas removal, low-temperature separation, and LPG product recovery.