Page 163 - Construction Waterproofing Handbook

P. 163

3.52 CHAPTER THREE

Following initial base-coat curing, within

24 hours intermediate coats, topcoats, and

aggregates are installed (Fig. 3.41).

Aggregate, silica sand, and silicon car-

bide are installed in intermediate or final

topcoats or possibly both in heavy traffic

areas. On pedestrian decks grit is added at a

2

rate of 4–10 lb square (100 ft ) of deck area.

FIGURE 3.35 Crack detailing. In traffic lanes, as much as 100–200 lb of

aggregate per square is added.

Aggregate is applied by hand seeding

(broadcasting) or by mechanical means (Fig. 3.42). If aggregate is added to a topcoat, it is

back-rolled for uniform thickness of membrane and grit distribution. With installations of

large aggregate amounts, an initial coat with aggregate fully loaded is first allowed to dry.

Excess aggregate is then swept off, and an additional topcoat is installed to lock in the grit

and act as an additional protective layer. See Fig. 3.43 for aggregate comparisons.

Intermediate coats usually range in thickness from 10 to 30 mil dry film, whereas top

coats range in thickness from 5 to 20 mil. Refer to Figs. 3.44 and 3.45 for typical millage

requirement. Final coats should cure 24–72 hours before traffic is allowed on the deck,

paint stripping is installed, and equipment is moved onto the deck. Approximate coverage

rates for various millage requirements are shown in Table 3.21. Trowel systems are applied

to considerably greater thickness than liquid-applied systems. Troweled systems range

1

1

from 8– 4 in total thickness, depending upon the aggregate used.

Other than applications of acrylic coatings, manufacturers require primers on all

substrates for improved membrane bonding to substrates. Primers are supplied for var-

ious substrates, including concrete, wood, metal, tile, stone, and previously coated sur-

faces. Additionally, priming of aggregate or grit is required before its installation in the

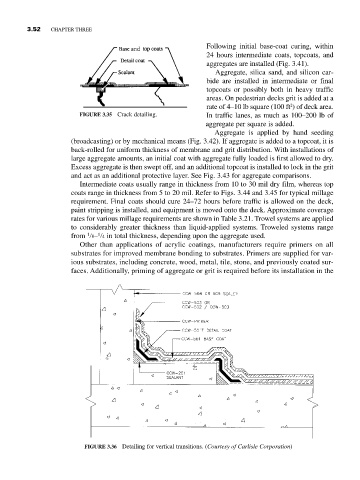

FIGURE 3.36 Detailing for vertical transitions. (Courtesy of Carlisle Corporation)