Page 288 - Construction Waterproofing Handbook

P. 288

5.46 CHAPTER FIVE

be covered with ice that is not visibly

noticeable but that will cause the sealant not

to bond to the substrate. Even if the sealant

is warmed sufficiently to melt this ice, the

resulting joint wetness will cause failure.

Therefore in freezing temperatures it is crit-

ical that joints be heated and dried before

sealant application.

Sealants in cold-weather conditions

should be stored in heated containers until

the actual application. Curing time is

slowed considerably, and sealants should be

protected from physical abuse during this

curing period.

With cold-weather joint applications, joints

are installed at their maximum width. These

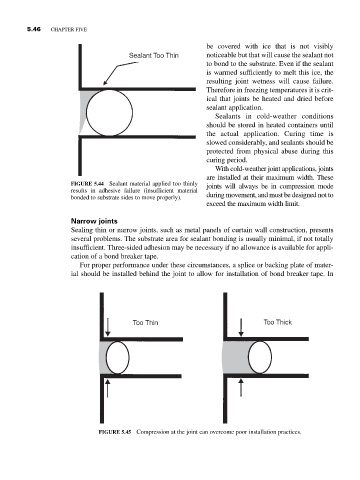

FIGURE 5.44 Sealant material applied too thinly joints will always be in compression mode

results in adhesive failure (insufficient material

bonded to substrate sides to move properly). during movement, and must be designed not to

exceed the maximum width limit.

Narrow joints

Sealing thin or narrow joints, such as metal panels of curtain wall construction, presents

several problems. The substrate area for sealant bonding is usually minimal, if not totally

insufficient. Three-sided adhesion may be necessary if no allowance is available for appli-

cation of a bond breaker tape.

For proper performance under these circumstances, a splice or backing plate of mater-

ial should be installed behind the joint to allow for installation of bond breaker tape. In

FIGURE 5.45 Compression at the joint can overcome poor installation practices.