Page 291 - Construction Waterproofing Handbook

P. 291

SEALANTS 5.49

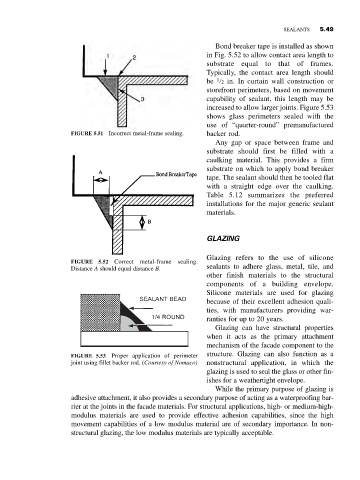

Bond breaker tape is installed as shown

in Fig. 5.52 to allow contact area length to

substrate equal to that of frames.

Typically, the contact area length should

1

be 2 in. In curtain wall construction or

storefront perimeters, based on movement

capability of sealant, this length may be

increased to allow larger joints. Figure 5.53

shows glass perimeters sealed with the

use of “quarter-round” premanufactured

FIGURE 5.51 Incorrect metal-frame sealing. backer rod.

Any gap or space between frame and

substrate should first be filled with a

caulking material. This provides a firm

substrate on which to apply bond breaker

tape. The sealant should then be tooled flat

with a straight edge over the caulking.

Table 5.12 summarizes the preferred

installations for the major generic sealant

materials.

GLAZING

Glazing refers to the use of silicone

FIGURE 5.52 Correct metal-frame sealing.

Distance A should equal distance B. sealants to adhere glass, metal, tile, and

other finish materials to the structural

components of a building envelope.

Silicone materials are used for glazing

because of their excellent adhesion quali-

ties, with manufacturers providing war-

ranties for up to 20 years.

Glazing can have structural properties

when it acts as the primary attachment

mechanism of the facade component to the

FIGURE 5.53 Proper application of perimeter structure. Glazing can also function as a

joint using fillet backer rod. (Courtesy of Nomaco) nonstructural application, in which the

glazing is used to seal the glass or other fin-

ishes for a weathertight envelope.

While the primary purpose of glazing is

adhesive attachment, it also provides a secondary purpose of acting as a waterproofing bar-

rier at the joints in the facade materials. For structural applications, high- or medium-high-

modulus materials are used to provide effective adhesion capabilities, since the high

movement capabilities of a low modulus material are of secondary importance. In non-

structural glazing, the low modulus materials are typically acceptable.