Page 289 - Construction Waterproofing Handbook

P. 289

SEALANTS 5.47

addition, sealants should be tooled flat and

flush, not concave, which would leave a

narrow section of material in the center.

Refer to Fig. 5.48.

Another alternative is to overband the

sealant onto sides of metal facing, as shown

in Fig. 5.49. Note that in this situation,

backing tape is brought up and onto the

joint side to prevent three-sided adhesion.

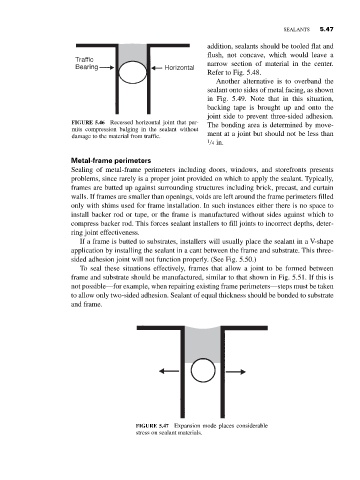

FIGURE 5.46 Recessed horizontal joint that per- The bonding area is determined by move-

mits compression bulging in the sealant without

damage to the material from traffic. ment at a joint but should not be less than

1 4 in.

Metal-frame perimeters

Sealing of metal-frame perimeters including doors, windows, and storefronts presents

problems, since rarely is a proper joint provided on which to apply the sealant. Typically,

frames are butted up against surrounding structures including brick, precast, and curtain

walls. If frames are smaller than openings, voids are left around the frame perimeters filled

only with shims used for frame installation. In such instances either there is no space to

install backer rod or tape, or the frame is manufactured without sides against which to

compress backer rod. This forces sealant installers to fill joints to incorrect depths, deter-

ring joint effectiveness.

If a frame is butted to substrates, installers will usually place the sealant in a V-shape

application by installing the sealant in a cant between the frame and substrate. This three-

sided adhesion joint will not function properly. (See Fig. 5.50.)

To seal these situations effectively, frames that allow a joint to be formed between

frame and substrate should be manufactured, similar to that shown in Fig. 5.51. If this is

not possible—for example, when repairing existing frame perimeters—steps must be taken

to allow only two-sided adhesion. Sealant of equal thickness should be bonded to substrate

and frame.

FIGURE 5.47 Expansion mode places considerable

stress on sealant materials.