Page 286 - Construction Waterproofing Handbook

P. 286

5.44 CHAPTER FIVE

FIGURE 5.40 Proper positioning of nozzle when applying sealant. (Courtesy of SWRI)

capacity caused by the lack of material

applied to the sides of the substrate as

shown in Fig. 5.44.

These failures both occur in the expan-

sion mode. It is interesting to note that these

problems can likely be prevented if the

sealant is applied when the joint is completely

expanded, or in its widest width stage. This

typically occurs when the temperature is the

coldest to be experienced over the life cycle

of the joint. Sealant applied under this con-

dition will always be in the compression

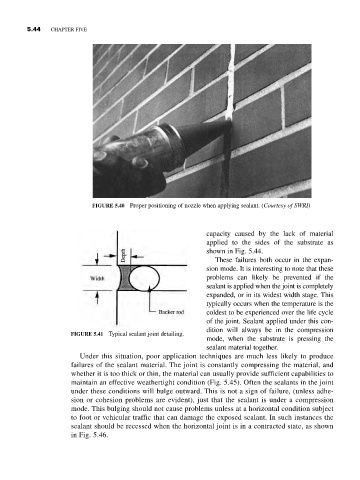

FIGURE 5.41 Typical sealant joint detailing.

mode, when the substrate is pressing the

sealant material together.

Under this situation, poor application techniques are much less likely to produce

failures of the sealant material. The joint is constantly compressing the material, and

whether it is too thick or thin, the material can usually provide sufficient capabilities to

maintain an effective weathertight condition (Fig. 5.45). Often the sealants in the joint

under these conditions will bulge outward. This is not a sign of failure, (unless adhe-

sion or cohesion problems are evident), just that the sealant is under a compression

mode. This bulging should not cause problems unless at a horizontal condition subject

to foot or vehicular traffic that can damage the exposed sealant. In such instances the

sealant should be recessed when the horizontal joint is in a contracted state, as shown

in Fig. 5.46.