Page 370 - Construction Waterproofing Handbook

P. 370

8.30 CHAPTER EIGHT

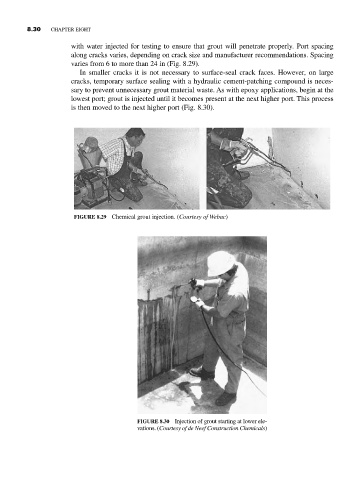

with water injected for testing to ensure that grout will penetrate properly. Port spacing

along cracks varies, depending on crack size and manufacturer recommendations. Spacing

varies from 6 to more than 24 in (Fig. 8.29).

In smaller cracks it is not necessary to surface-seal crack faces. However, on large

cracks, temporary surface sealing with a hydraulic cement-patching compound is neces-

sary to prevent unnecessary grout material waste. As with epoxy applications, begin at the

lowest port; grout is injected until it becomes present at the next higher port. This process

is then moved to the next higher port (Fig. 8.30).

FIGURE 8.29 Chemical grout injection. (Courtesy of Webac)

FIGURE 8.30 Injection of grout starting at lower ele-

vations. (Courtesy of de Neef Construction Chemicals)