Page 375 - Construction Waterproofing Handbook

P. 375

REMEDIAL WATERPROOFING 8.35

Gunite or shotcrete mixtures used with this equipment vary from field ratio mixes to

premixed manufactured dry materials requiring only the addition of water. Materials are

applied as a dry mix for vertical applications. After initial application, materials are trow-

eled or finished in place as necessary.

Surface preparation requires chipping and removal of all unsound substrate areas and

repairing of existing reinforcing steel as necessary. Additional reinforcing steel may also

be installed if necessary before gunite operations.

Overlays

Cementitious overlays are used for restoring deteriorated horizontal concrete substrates.

Overlays are available in a wide range of mixtures containing various admixtures that add

strength and shorten curing time. They are used in a variety of applications including

bridge repairs and parking deck restorations.

Often they are sufficiently watertight to eliminate a need for waterproofing coatings.

Others are designed specifically for use as an underlay for deck coating applications. If

additional structural strength is necessary, qualified engineers should be consulted for

selection and use of such products.

These materials are usually self-leveling, conforming to existing deck contours to

which they are applied. They are used also to fill ponding or low areas of existing decks

before deck-coating application, Fig. 8.38. Stiffer mixes are available for ramp areas and

inclined areas. (See Table 8.10.)

ELECTRO-OSMOSIS

Electro-osmosis is a process that introduces electric current into a substrate to control the

flow of water and humidity, a process originally identified in the early 1800s. The electro-

osmosis process is now available commercially and used for a variety of construction tech-

niques including removal of hazardous contamination from groundwater and facilitating

dewatering of soils.

Electro-osmosis is also used today as an effective remedial waterproofing and humidity

control method, but only for concrete structures at or below-grade. The process creates a

pulsating direct current (DC) electrical current that causes cations within the concrete to

move from the dry or interior side of a structure to the wet or exterior side. The movement

of cations attracts the available water and moisture to follow, against the flow induced by

the hydrostatic pressure, eliminating water infiltration into the structure.

A commercial electro-osmotic pulse system (EOP) consists of a control unit that plugs

directly into a common 110-volt outlet that delivers electric pulses to an anode (positive

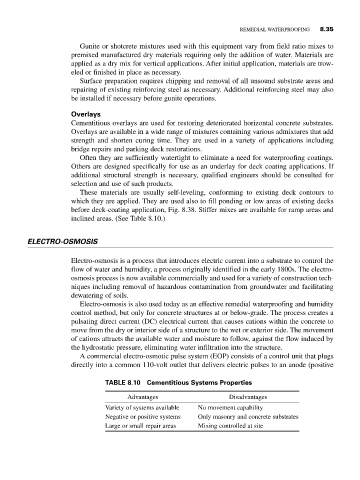

TABLE 8.10 Cementitious Systems Properties

Advantages Disadvantages

Variety of systems available No movement capability

Negative or positive systems Only masonry and concrete substrates

Large or small repair areas Mixing controlled at site