Page 371 - Construction Waterproofing Handbook

P. 371

REMEDIAL WATERPROOFING 8.31

Pressures required to inject materials are generally 300–500 lb/in (Fig. 8.31). After

2

injection, material should completely cure before injection ports are removed, approxi-

mately 24 hours. Portholes should then be patched with quick-set hydraulic patching mate-

rial. Excess grout is then removed from the repair area (Fig. 8.32).

Chemical grouts should not be used in temperatures below 40°F nor on frozen substrates.

Chemical grout materials are flammable and hazardous. Extreme care should be taken dur-

ing its use and storage, as well as in the disposal of the chemical waste. In confined spaces,

ventilation and respirators are required for safe working conditions.

CEMENTITIOUS PATCHING COMPOUNDS

For restoration of concrete and masonry substrates, a host of cementitious-based products

is available to restore substrates to a sound condition before remedial waterproofing appli-

cations. These cement-based products are high-strength, dry mixes, with integrally mixed

FIGURE 8.31 Mechanical grout injector. (Courtesy of Webac)

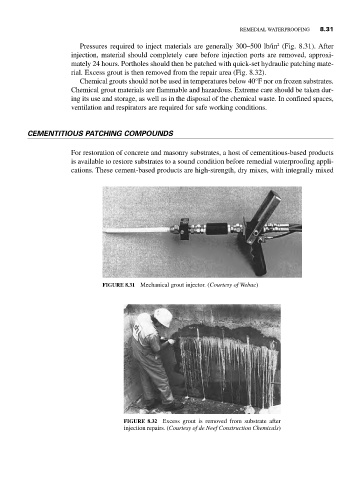

FIGURE 8.32 Excess grout is removed from substrate after

injection repairs. (Courtesy of de Neef Construction Chemicals)