Page 405 - Construction Waterproofing Handbook

P. 405

THE BUILDING ENVELOPE: PUTTING IT ALL TOGETHER 10.7

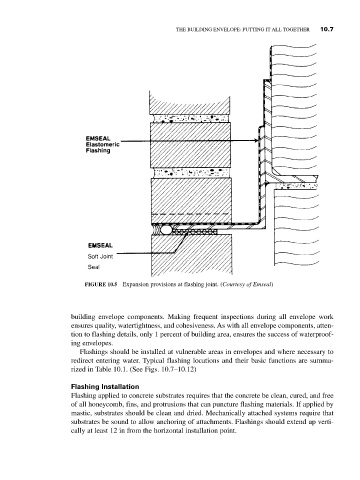

FIGURE 10.5 Expansion provisions at flashing joint. (Courtesy of Emseal)

building envelope components. Making frequent inspections during all envelope work

ensures quality, watertightness, and cohesiveness. As with all envelope components, atten-

tion to flashing details, only 1 percent of building area, ensures the success of waterproof-

ing envelopes.

Flashings should be installed at vulnerable areas in envelopes and where necessary to

redirect entering water. Typical flashing locations and their basic functions are summa-

rized in Table 10.1. (See Figs. 10.7–10.12)

Flashing Installation

Flashing applied to concrete substrates requires that the concrete be clean, cured, and free

of all honeycomb, fins, and protrusions that can puncture flashing materials. If applied by

mastic, substrates should be clean and dried. Mechanically attached systems require that

substrates be sound to allow anchoring of attachments. Flashings should extend up verti-

cally at least 12 in from the horizontal installation point.