Page 409 - Construction Waterproofing Handbook

P. 409

THE BUILDING ENVELOPE: PUTTING IT ALL TOGETHER 10.11

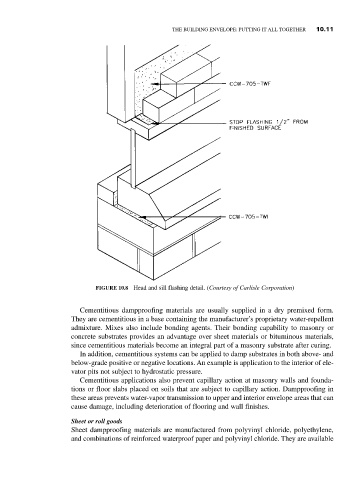

FIGURE 10.8 Head and sill flashing detail. (Courtesy of Carlisle Corporation)

Cementitious dampproofing materials are usually supplied in a dry premixed form.

They are cementitious in a base containing the manufacturer’s proprietary water-repellent

admixture. Mixes also include bonding agents. Their bonding capability to masonry or

concrete substrates provides an advantage over sheet materials or bituminous materials,

since cementitious materials become an integral part of a masonry substrate after curing.

In addition, cementitious systems can be applied to damp substrates in both above- and

below-grade positive or negative locations. An example is application to the interior of ele-

vator pits not subject to hydrostatic pressure.

Cementitious applications also prevent capillary action at masonry walls and founda-

tions or floor slabs placed on soils that are subject to capillary action. Dampproofing in

these areas prevents water-vapor transmission to upper and interior envelope areas that can

cause damage, including deterioration of flooring and wall finishes.

Sheet or roll goods

Sheet dampproofing materials are manufactured from polyvinyl chloride, polyethylene,

and combinations of reinforced waterproof paper and polyvinyl chloride. They are available