Page 406 - Construction Waterproofing Handbook

P. 406

10.8 CHAPTER TEN

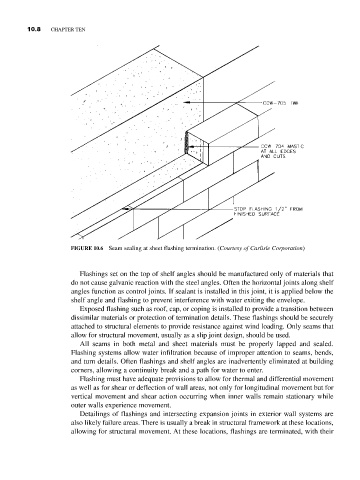

FIGURE 10.6 Seam sealing at sheet flashing termination. (Courtesy of Carlisle Corporation)

Flashings set on the top of shelf angles should be manufactured only of materials that

do not cause galvanic reaction with the steel angles. Often the horizontal joints along shelf

angles function as control joints. If sealant is installed in this joint, it is applied below the

shelf angle and flashing to prevent interference with water exiting the envelope.

Exposed flashing such as roof, cap, or coping is installed to provide a transition between

dissimilar materials or protection of termination details. These flashings should be securely

attached to structural elements to provide resistance against wind loading. Only seams that

allow for structural movement, usually as a slip joint design, should be used.

All seams in both metal and sheet materials must be properly lapped and sealed.

Flashing systems allow water infiltration because of improper attention to seams, bends,

and turn details. Often flashings and shelf angles are inadvertently eliminated at building

corners, allowing a continuity break and a path for water to enter.

Flashing must have adequate provisions to allow for thermal and differential movement

as well as for shear or deflection of wall areas, not only for longitudinal movement but for

vertical movement and shear action occurring when inner walls remain stationary while

outer walls experience movement.

Detailings of flashings and intersecting expansion joints in exterior wall systems are

also likely failure areas. There is usually a break in structural framework at these locations,

allowing for structural movement. At these locations, flashings are terminated, with their