Page 480 - Construction Waterproofing Handbook

P. 480

12.20 CHAPTER TWELVE

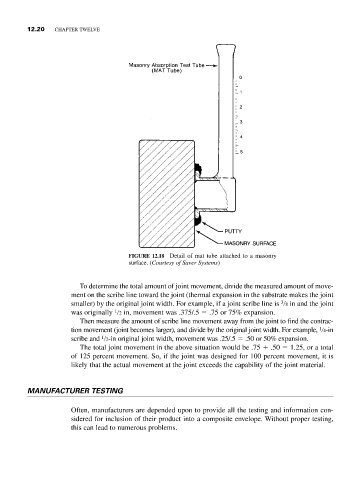

FIGURE 12.18 Detail of mat tube attached to a masonry

surface. (Courtesy of Saver Systems)

To determine the total amount of joint movement, divide the measured amount of move-

ment on the scribe line toward the joint (thermal expansion in the substrate makes the joint

3

smaller) by the original joint width. For example, if a joint scribe line is 8 in and the joint

1

was originally 2 in, movement was .375/.5 .75 or 75% expansion.

Then measure the amount of scribe line movement away from the joint to find the contrac-

1

tion movement (joint becomes larger), and divide by the original joint width. For example, 4-in

scribe and 2-in original joint width, movement was .25/.5 .50 or 50% expansion.

1

The total joint movement in the above situation would be .75 .50 1.25, or a total

of 125 percent movement. So, if the joint was designed for 100 percent movement, it is

likely that the actual movement at the joint exceeds the capability of the joint material.

MANUFACTURER TESTING

Often, manufacturers are depended upon to provide all the testing and information con-

sidered for inclusion of their product into a composite envelope. Without proper testing,

this can lead to numerous problems.