Page 84 - Construction Waterproofing Handbook

P. 84

BELOW-GRADE WATERPROOFING 2.47

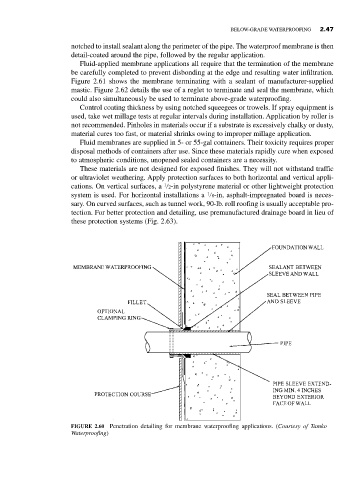

notched to install sealant along the perimeter of the pipe. The waterproof membrane is then

detail-coated around the pipe, followed by the regular application.

Fluid-applied membrane applications all require that the termination of the membrane

be carefully completed to prevent disbonding at the edge and resulting water infiltration.

Figure 2.61 shows the membrane terminating with a sealant of manufacturer-supplied

mastic. Figure 2.62 details the use of a reglet to terminate and seal the membrane, which

could also simultaneously be used to terminate above-grade waterproofing.

Control coating thickness by using notched squeegees or trowels. If spray equipment is

used, take wet millage tests at regular intervals during installation. Application by roller is

not recommended. Pinholes in materials occur if a substrate is excessively chalky or dusty,

material cures too fast, or material shrinks owing to improper millage application.

Fluid membranes are supplied in 5- or 55-gal containers. Their toxicity requires proper

disposal methods of containers after use. Since these materials rapidly cure when exposed

to atmospheric conditions, unopened sealed containers are a necessity.

These materials are not designed for exposed finishes. They will not withstand traffic

or ultraviolet weathering. Apply protection surfaces to both horizontal and vertical appli-

1

cations. On vertical surfaces, a 2-in polystyrene material or other lightweight protection

system is used. For horizontal installations a 8-in, asphalt-impregnated board is neces-

1

sary. On curved surfaces, such as tunnel work, 90-lb. roll roofing is usually acceptable pro-

tection. For better protection and detailing, use premanufactured drainage board in lieu of

these protection systems (Fig. 2.63).

FIGURE 2.60 Penetration detailing for membrane waterproofing applications. (Courtesy of Tamko

Waterproofing)