Page 88 - Construction Waterproofing Handbook

P. 88

BELOW-GRADE WATERPROOFING 2.51

polyethylene film attached. Self-adhering membranes adhere to themselves, eliminating

the need for a seam adhesive. Sheets are manufactured in varying widths of 3–4 ft and

typically 50-ft lengths.

Also available are rubberized asphalt sheets reinforced with glass cloth weave that require

compatible asphalt adhesives for adhering to a substrate. Rubber asphalt products require a

protection layer, to prevent damage during backfill or concrete placement operations.

Self-adhering asphalt membranes include a polyethylene film that acts as an additional

layer of protection against water infiltration and weathering. The self-adhering portion is

protected with a release paper, which is removed to expose the adhesive for placement.

Being virtually self-contained, except for primers, this system is the simplest of all sheet

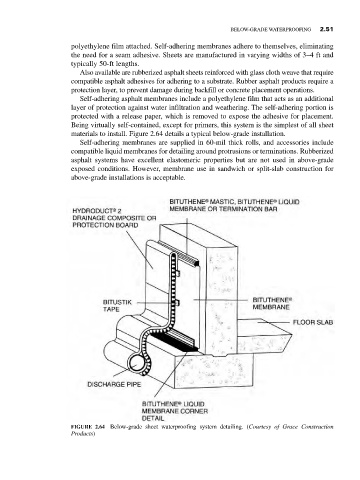

materials to install. Figure 2.64 details a typical below-grade installation.

Self-adhering membranes are supplied in 60-mil thick rolls, and accessories include

compatible liquid membranes for detailing around protrusions or terminations. Rubberized

asphalt systems have excellent elastomeric properties but are not used in above-grade

exposed conditions. However, membrane use in sandwich or split-slab construction for

above-grade installations is acceptable.

FIGURE 2.64 Below-grade sheet waterproofing system detailing. (Courtesy of Grace Construction

Products)