Page 85 - Construction Waterproofing Handbook

P. 85

2.48 CHAPTER TWO

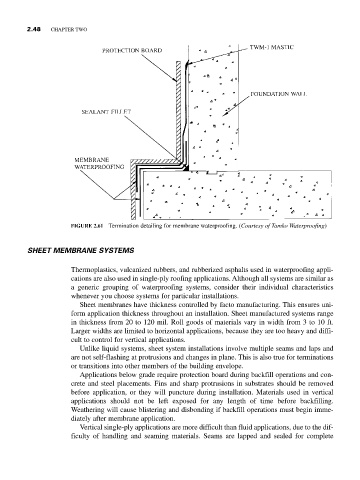

FIGURE 2.61 Termination detailing for membrane waterproofing. (Courtesy of Tamko Waterproofing)

SHEET MEMBRANE SYSTEMS

Thermoplastics, vulcanized rubbers, and rubberized asphalts used in waterproofing appli-

cations are also used in single-ply roofing applications. Although all systems are similar as

a generic grouping of waterproofing systems, consider their individual characteristics

whenever you choose systems for particular installations.

Sheet membranes have thickness controlled by facto manufacturing. This ensures uni-

form application thickness throughout an installation. Sheet manufactured systems range

in thickness from 20 to 120 mil. Roll goods of materials vary in width from 3 to 10 ft.

Larger widths are limited to horizontal applications, because they are too heavy and diffi-

cult to control for vertical applications.

Unlike liquid systems, sheet system installations involve multiple seams and laps and

are not self-flashing at protrusions and changes in plane. This is also true for terminations

or transitions into other members of the building envelope.

Applications below grade require protection board during backfill operations and con-

crete and steel placements. Fins and sharp protrusions in substrates should be removed

before application, or they will puncture during installation. Materials used in vertical

applications should not be left exposed for any length of time before backfilling.

Weathering will cause blistering and disbonding if backfill operations must begin imme-

diately after membrane application.

Vertical single-ply applications are more difficult than fluid applications, due to the dif-

ficulty of handling and seaming materials. Seams are lapped and sealed for complete